- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

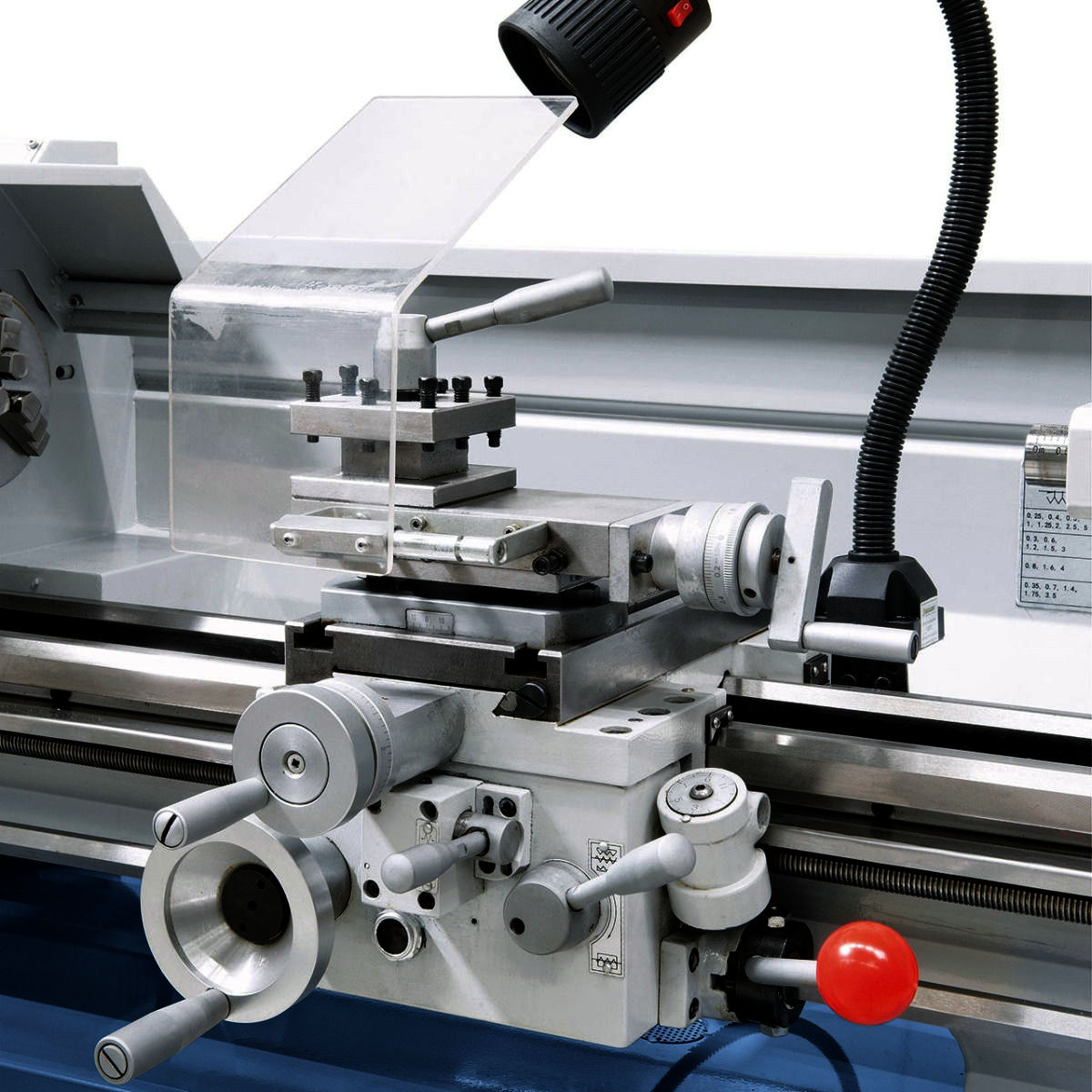

BENCH LATHE GH600-

GH600

The turning lathe GH600 is serially equipped with a leadscrew and feed rod for thread cutting and the automatic longitudinal and cross feed. The 12-step control gear allow a quick adjustment of the speed - not belt change necessary. The compact construction and the high own weight guarantees smooth running and precise work.

Properties

-

Control gear allows easy and quick speed change

-

High-quality tapered rollerbearings ensure high concentricity of spindle nose (≤ 0,009 mm)

-

Powerful motor for high torque, speed range 45 - 2000 rpm

-

Wide range of applications: precision mechanics, training and education, etc.

-

Logically arranged feed setting allows easy, smooth adjustment

-

Solid machine bed with inductive hardened and polished guideways

-

Ideal for processing steel, non-ferrous metals and plastics

-

Comes complete with feed rod for automatic longitudinal and cross feed

-

Apron features handwheels with fine scale

Distance between centers

600 mm

Center height

140 mm

Swing over bed

280 mm

Bed width

150 mm

Spindle bore

26 mm

Taper at spindle bore

MT 4

Speed range

(12) 45 - 2000 rpm

Longitudinal feed

0,044 - 0,437 mm/rev.

Cross feed

0,022 - 0,218 mm/rev.

Metric thread

(30) 0,25 - 5 mm

Inch thread

(20) 6 - 96 threads/1"

Travel of tailstock sleeve

110 mm

Taper of tailstock sleeve

MT 3

Motor power output S1 100%

0,75 kW / 230 V

Motor power input S6 40%

1,0 kW / 230 V

Machine dimension (W x D x H)*

1220 x 700 x 500 mm

Weight approx.

220 kg

Standard accessories

-

3-jaw chuck 125 mm

-

Flange 125 mm

-

Cross slide with top support

-

Dead centers

-

Thread dial

-

Change gears

-

4-way tool post holder

-

LED machine light

-

Chuck guard

-

Splash guard

-

Leadscrew cover

-

Tools

The turning lathe GH600 is serially equipped with a leadscrew and feed rod for thread cutting and the automatic longitudinal and cross feed. The 12-step control gear allow a quick adjustment of the speed - not belt change necessary. The compact construction and the high own weight guarantees smooth running and precise work.

Properties

-

Control gear allows easy and quick speed change

-

High-quality tapered rollerbearings ensure high concentricity of spindle nose (≤ 0,009 mm)

-

Powerful motor for high torque, speed range 45 - 2000 rpm

-

Wide range of applications: precision mechanics, training and education, etc.

-

Logically arranged feed setting allows easy, smooth adjustment

-

Solid machine bed with inductive hardened and polished guideways

-

Ideal for processing steel, non-ferrous metals and plastics

-

Comes complete with feed rod for automatic longitudinal and cross feed

-

Apron features handwheels with fine scale

Distance between centers

600 mm

Center height

140 mm

Swing over bed

280 mm

Bed width

150 mm

Spindle bore

26 mm

Taper at spindle bore

MT 4

Speed range

(12) 45 - 2000 rpm

Longitudinal feed

0,044 - 0,437 mm/rev.

Cross feed

0,022 - 0,218 mm/rev.

Metric thread

(30) 0,25 - 5 mm

Inch thread

(20) 6 - 96 threads/1"

Travel of tailstock sleeve

110 mm

Taper of tailstock sleeve

MT 3

Motor power output S1 100%

0,75 kW / 230 V

Motor power input S6 40%

1,0 kW / 230 V

Machine dimension (W x D x H)*

1220 x 700 x 500 mm

Weight approx.

220 kg

Standard accessories

-

3-jaw chuck 125 mm

-

Flange 125 mm

-

Cross slide with top support

-

Dead centers

-

Thread dial

-

Change gears

-

4-way tool post holder

-

LED machine light

-

Chuck guard

-

Splash guard

-

Leadscrew cover

-

Tools