- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

Boring Machine JRT60-

JRT60

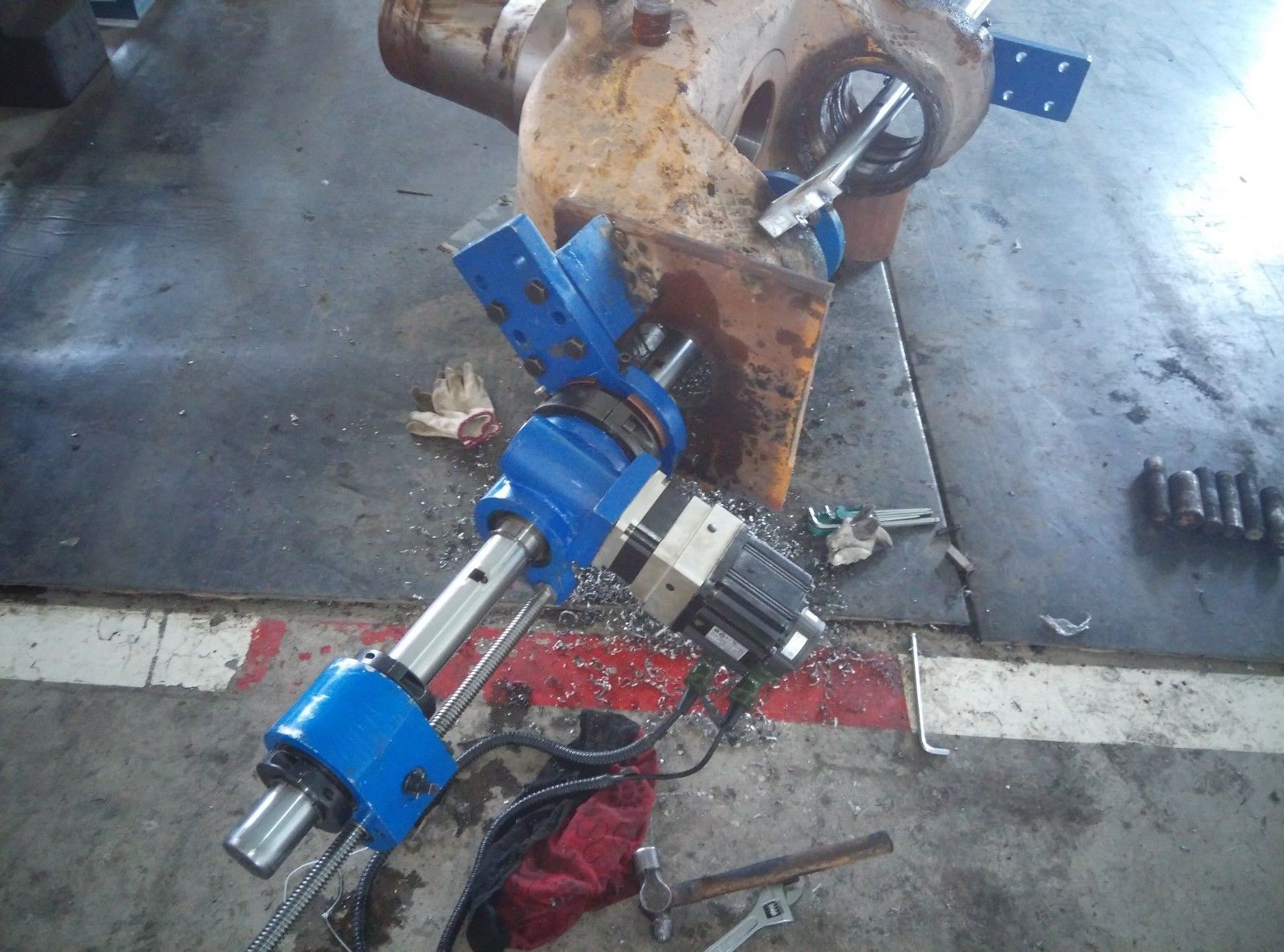

Versatile precision Portable Boring Machine Bore Range 65-700mm with Facing Tool

Machine Performance:

JRT60 portable boring machine is powerful and mainly used for line boring and facing operations, such as: repairing the inner wall of the pipes,crane rotary holes,stern shaft holes and rudder holes.

1.Power

Power provided by a servo motor enables constant torque output ,and boring large diameter holes with deep cuts. The motor can be replaced by a hydraulic power unit.

2.Feed unit

The axial feed unit is driven by a screw mechanism without using a single motor which makes operation easy.

3.Bearing support

There is a high precision bearing in the support unit, Each supporting leg is individually adjustable, allowing quickly center the mounting inside bores which are not completely round. The inner diameter of the bearing can be adjusted.

4.Tool holder

JRT60 are equipped with five tools holders ,which are adjustable for a wide range of finish machining bores from 65 to 700mm

5.Facing unit

This rugged, heavy-duty facing head has a very high removal rate in handling large diameter facing jobs with ease,The facing head mounts on anywhere along the bar and feed speed is also stepless so you can select suitable feed speed according to your work.

Specification

JRT60 portable boring machine specification(standard)<o:p>

Name<o:p>

Parameter<o:p>

Remarks<o:p>

Model<o:p>

JRT60<o:p>

Standard Boring bar diameter<o:p>

60mm×2000mm

Customizable<o:p>

Boring diameter<o:p>

65-700mm<o:p>

Axial feed per revolution

0-0.6mm/r<o:p>

Power<o:p>

2.2Kw electric motor 380V<o:p>

Hydraulic available

Facing Diameter(Optional)<o:p>

80-800mm<o:p>

Facing feed per revolution<o:p>

0-0.6mm/r

Roating speed<o:p>

0-30rpm<o:p>

JRT60 Standard configuration list<o:p>

Name<o:p>

Parameter<o:p>

QTY

1<o:p>

servomotor

1 set<o:p>

2<o:p>

control console<o:p>

1 pc<o:p>

3<o:p>

speed reducer

1 set 4<o:p>

leadscrew (700mm)<o:p>

1 pc

5<o:p>

Single Arm Mount with spherical bearing<o:p>

2 pcs<o:p>

6<o:p>

2.2Kw Electric motor(Control box included)<o:p>

1<o:p>

7<o:p>

Universal Arm Mount with spherical bearing<o:p>

2 pcs<o:p>

8<o:p>

Boring Bar 60x2000 with 12 mm tooling holes every 254.0 mm

1 pc<o:p>

9<o:p>

tools holders + cutting tools (for a wide range of finish machining bores from 65 to 700mm)<o:p>

1 set<o:p>

10<o:p>

Measuring tools for proper installation of the cutting tool and measuring the diameter of the hole without disassembling the machine<o:p>

1 set<o:p>

11<o:p>

ID mount self-aligning bearing support assembly for processing diameters 500 - 700 mm<o:p>

1 set<o:p>

12<o:p>

tools for assembly and installation of the machine<o:p>

1 set

13<o:p>

Small setup cones (70 - 213 mm)<o:p>

2 pcs

14<o:p>

Large setup cones (213 - 305 mm)<o:p>

2 pcs

More products

Jierui Machine Portable Boring Machines

ItemBoring bar Diameter(MM)Boring Diameter(mm)Strok(mm)PowerFeed SpeedJRT4040*1500(customizable)45*2003901.5kw0-100(mm/min)JRT50

50*1500(customizable)

55*2503901.5kw0-100(mm/min)JRT60<o:p> 60*2000(customizable)

65*7002.2kw0-0.6mm/rJRT90

90*3000(customizable)

95-900Hydraulic/Servomotor 3KW0-0.6mm/rJRT110

110*3500(customizable)

180-1000Hydraulic motor0-0.6mm/rJRT150

150*3500(customizable)

270-1800Hydraulic motor0-0.6mm/rBB50

50*1500 (customizable)

55-3504002.2Kw electric moto0-0.5mm/rYK60

60*1500(customizable)

65-400350eibenstock 1.8KwGermany

Versatile precision Portable Boring Machine Bore Range 65-700mm with Facing Tool

Machine Performance:

JRT60 portable boring machine is powerful and mainly used for line boring and facing operations, such as: repairing the inner wall of the pipes,crane rotary holes,stern shaft holes and rudder holes.

1.Power

Power provided by a servo motor enables constant torque output ,and boring large diameter holes with deep cuts. The motor can be replaced by a hydraulic power unit.

2.Feed unit

The axial feed unit is driven by a screw mechanism without using a single motor which makes operation easy.

3.Bearing support

There is a high precision bearing in the support unit, Each supporting leg is individually adjustable, allowing quickly center the mounting inside bores which are not completely round. The inner diameter of the bearing can be adjusted.

4.Tool holder

JRT60 are equipped with five tools holders ,which are adjustable for a wide range of finish machining bores from 65 to 700mm

5.Facing unit

This rugged, heavy-duty facing head has a very high removal rate in handling large diameter facing jobs with ease,The facing head mounts on anywhere along the bar and feed speed is also stepless so you can select suitable feed speed according to your work.

Specification

JRT60 portable boring machine specification(standard)<o:p>

Name<o:p>

Parameter<o:p>

Remarks<o:p>

Model<o:p>

JRT60<o:p>

Standard Boring bar diameter<o:p>

60mm×2000mm

Customizable<o:p>

Boring diameter<o:p>

65-700mm<o:p>

Axial feed per revolution

0-0.6mm/r<o:p>

Power<o:p>

2.2Kw electric motor 380V<o:p>

Hydraulic available

Facing Diameter(Optional)<o:p>

80-800mm<o:p>

Facing feed per revolution<o:p>

0-0.6mm/r

Roating speed<o:p>

0-30rpm<o:p>

JRT60 Standard configuration list<o:p>

Name<o:p>

Parameter<o:p>

QTY

1<o:p>

servomotor

1 set<o:p>

2<o:p>

control console<o:p>

1 pc<o:p>

3<o:p>

speed reducer

1 set 4<o:p>

leadscrew (700mm)<o:p>

1 pc

5<o:p>

Single Arm Mount with spherical bearing<o:p>

2 pcs<o:p>

6<o:p>

2.2Kw Electric motor(Control box included)<o:p>

1<o:p>

7<o:p>

Universal Arm Mount with spherical bearing<o:p>

2 pcs<o:p>

8<o:p>

Boring Bar 60x2000 with 12 mm tooling holes every 254.0 mm

1 pc<o:p>

9<o:p>

tools holders + cutting tools (for a wide range of finish machining bores from 65 to 700mm)<o:p>

1 set<o:p>

10<o:p>

Measuring tools for proper installation of the cutting tool and measuring the diameter of the hole without disassembling the machine<o:p>

1 set<o:p>

11<o:p>

ID mount self-aligning bearing support assembly for processing diameters 500 - 700 mm<o:p>

1 set<o:p>

12<o:p>

tools for assembly and installation of the machine<o:p>

1 set

13<o:p>

Small setup cones (70 - 213 mm)<o:p>

2 pcs

14<o:p>

Large setup cones (213 - 305 mm)<o:p>

2 pcs

More products

Jierui Machine Portable Boring Machines

ItemBoring bar Diameter(MM)Boring Diameter(mm)Strok(mm)PowerFeed SpeedJRT4040*1500(customizable)45*2003901.5kw0-100(mm/min)JRT50

50*1500(customizable)

55*2503901.5kw0-100(mm/min)JRT60<o:p> 60*2000(customizable)

65*7002.2kw0-0.6mm/rJRT90

90*3000(customizable)

95-900Hydraulic/Servomotor 3KW0-0.6mm/rJRT110

110*3500(customizable)

180-1000Hydraulic motor0-0.6mm/rJRT150

150*3500(customizable)

270-1800Hydraulic motor0-0.6mm/rBB50

50*1500 (customizable)

55-3504002.2Kw electric moto0-0.5mm/rYK60

60*1500(customizable)

65-400350eibenstock 1.8KwGermany