- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

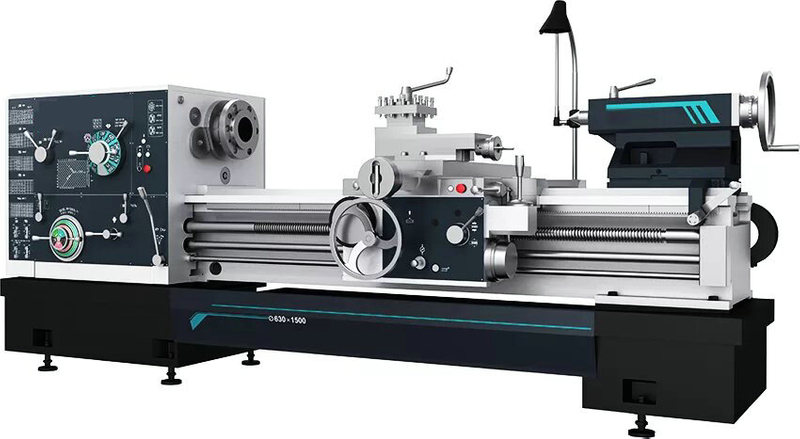

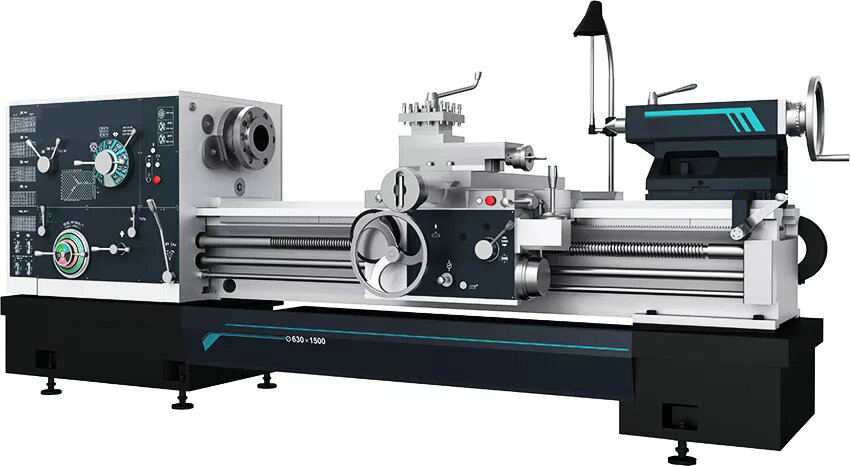

CW-E series conventional latheYou are here: Home » Products » TURNING » INDUSTRIAL HEAVY DUTY LATHE » CW-E series conventional latheCW-E series conventional lathe

Availability: Quantity: The CDS-B/C series conventional lathes are general-purpose lathes developed by our company in collaboration with renowned global lathe manufacturing enterprises.

Application Field:

The CDS-B/C series conventional lathes, developed by our company in collaboration with renowned global lathe manufacturing enterprises, are user-friendly general-purpose lathes. They feature a popular angular flat design with spacious front and rear legs. The bed guide rails have undergone surface high-frequency quenching and grinding processes, achieving a quenching hardness of G50. The headstock gearbox has undergone high-frequency quenching of the gear teeth and precision gear grinding, with gear precision reaching levels 6 to 7. This machine can process materials such as steel, cast iron, non-ferrous metals, and non-metallic materials. Parts processed on this machine can achieve a dimensional accuracy of IT7 and a surface roughness of 1.6.

Machine Features:

1. Large Spindle Bore: B-type with 82mm, C-type with 105mm.

2. High Spindle Speed: The spindle system is dynamically balanced, allowing for high rotational speeds and comprehensive adaptability to tooling techniques.

3. High Rigidity: The main body of the machine tool is made entirely of resin-bonded high-phosphorus castings, and the structure of the main body of the machine tool is made more rational through finite element analysis and optimization.

4. Aging Treatment for Bed Body, High-Frequency Quenching for Guide Rails: Enhances the machine tool's longevity.

5. Precision Grinding for Bed Guide Rails: Ensures high precision along the entire length of the guide rails.

6. Vertical Lead Screw Equipped with Metal Protective Cover: Enhances the personal safety of operators.

7. Rapid Traverse Mechanism in Both Vertical and Horizontal Directions on the Carriage: Makes the operation of the machine tool more convenient and efficient for operators.-

CW6263E/CW6280E/CW62100E

Product Description

High precision heavy duty Lathe Machine Price Torno CW6163E/CW6263E

Product Presentation

CW-E series horizontal lathes can undertake various turning jobs, mainly for turning inner and outer cylindrical surfaces, conical surfaces and other parts with rotating surfaces. Turning of end faces, grooving, cutting, drilling, and turning of various commonly used metric, inch, modulus and diametral threads. This machine tool is especially suitable for small batch production processing workshops and mechanical repair workshops, and can process steel, cast iron and non-ferrous metals and other materials. The main difference between a horizontal lathe and a saddle lathe is that the saddle lathe has a bed with a detachable saddle, which expands the range of processing diameters, and is very suitable for the processing of disc parts and deformed parts. It can provide various combinations of metric machine tools, inch machine tools and various special functions. The dimensional accuracy of the processed parts on this machine tool can reach IT7 level, and the surface roughness can reach Ra1.6 level.

Standard configurations

3-Jaw chuck 4-way tool post

Steady rest(≥3000mm-Standard <3000mm-Option)

Follow rest(≥3000mm-Standard <3000mm-Option)

Standard toolkit

Optional configurations

4-Jaw chuck Chuck guard

Tool post guard Rear splash guard

Ø130Diameter of spindle bore 15kW spindle motor

Center of tailstock Face plate Thread dial

Drive plate Taper-turning attachment DRO

Anchor bolts Spindle center and center sleeve

Adjustable pads Foot brake(1000mm~3000mm Available)

Product model UNIT CW6163E CW6263E CW6180E CW6280E CW61100E CW62100E specification Max. swing diameter over bed mm Ø630 Ø800 Ø1000 Max.swing diameter over cross slide mm Ø350 Ø480 Ø710 Max.swing diameter in gap mm — Ø800 — Ø1000 — Ø1230 Length in gap mm — 350 — 350 — 350 Max. workpiece length mm 1000/1500/2000/3000/4000/5000/6000 Max. cutting length CW61xxx mm 850/1350/1850/2850/3850/4850/5850 CW62xxx 600/1100/1600/2600/3600/4600/5600 Spindle spindle nose C11 *D11 Spindle bore mm Ø100(C11)(Allowable bar diameter≤Ø98)

*Ø105(D11)(Allowable bar diameter≤Ø103)

opt:Ø130(Allowable bar diameter≤Ø128)Chuck size mm Ø315 Ø400 Ø400 Taper of spindle bore Metric 120(1:20)

Opt:Spindle bore Ø130- Metric 140(1:20)Max.Spindle torque Nm 2400 Spindle speed ranges rpm 7.5-1000(18 speeds) Spindle centre height mm 315 400 515 Spindle motor power 11kw/1460rpm(50HZ) Opt:15kw/1460rpm(50HZ) Tailstock Diameter of tailstock quill mm Ø100 Travel of tailstock quill mm 250 Taper of tailstock quill No.6 MT Feeds&Threads (metric screw *inch screw) Longitudinal feed metric screw mm/r 64 Speeds 1/1 0.1-1.52 ; 16/1 1.6-24.3 inch screw in/r 64 Speeds *1/1 0.0019〜0.0612 ; *16/1 0.0305-0.98 Cross feed 1/2 times of the longitudinal feed Metric threads mm 0.5〜240 (52 Kinds)

*1-256 (57 Kinds)1-240 (50 Kinds)

*1-256 (57 Kinds)0.5〜240 (52 Kinds)

*1-256 (57 Kinds)Modular threads mm 0.5 〜120 (53 Kinds) *0.5 〜128 (57 Kinds) Inch threads TPI 28-1(34 Kinds)

*32〜1/16(67 Kinds)14-1(26 Kinds)

*32-1/16(67 Kinds)28-1(34 Kinds)

*32-1/16(67 Kinds)Diametral pitch threads DP 28-1(24 Kinds) *32〜1/8(57 Kinds) Tool post Max.tool shank size mm 30X30 Travel of top slide mm 200 Swivel angle of top slide ±90° machine dimensions

(L*W*H)mm 3180X1340X1830(1000) 3630X1340X1830 (1500) 4230X1340X1830(2000) 5130X1340X1830(3000) 6040X1430X1830(4000) 7120X1430X1830(5000) 8240X1430X1830(6000) 3180X1380X1830(1000) 3630X1380X1830(1500) 4230X1380X1830 (2000) 5130X1380X1830 (3000) 6040X1470X1830 (4000) 7120X1470X1830 (5000) 8240X1470X1830(6000) 3180X1460X1830(1000) 3630X1460X1830 (1500) 4230X1460X1830(2000) 5130X1460X1830(3000) 6040X1550X1830 (4000) 7120X1550X1830(5000) 8240X1550X1830(6000) Machine weight CW61xxx kg 3900/4200/4500/5000/

5800/6500/73004100/4400/4700/5200/

6500/7200/77004350/4650/4950/5450/

6800/7300CW62xxx 4050/4350/4650/5150/

5950/6650/74504250/4550/4850/5350/

6600/7300/78504500/4800/5100/5600/

6950/7450Product Description

High precision heavy duty Lathe Machine Price Torno CW6163E/CW6263E

Product Presentation

CW-E series horizontal lathes can undertake various turning jobs, mainly for turning inner and outer cylindrical surfaces, conical surfaces and other parts with rotating surfaces. Turning of end faces, grooving, cutting, drilling, and turning of various commonly used metric, inch, modulus and diametral threads. This machine tool is especially suitable for small batch production processing workshops and mechanical repair workshops, and can process steel, cast iron and non-ferrous metals and other materials. The main difference between a horizontal lathe and a saddle lathe is that the saddle lathe has a bed with a detachable saddle, which expands the range of processing diameters, and is very suitable for the processing of disc parts and deformed parts. It can provide various combinations of metric machine tools, inch machine tools and various special functions. The dimensional accuracy of the processed parts on this machine tool can reach IT7 level, and the surface roughness can reach Ra1.6 level.

Standard configurations

3-Jaw chuck 4-way tool post

Steady rest(≥3000mm-Standard <3000mm-Option)

Follow rest(≥3000mm-Standard <3000mm-Option)

Standard toolkit

Optional configurations

4-Jaw chuck Chuck guard

Tool post guard Rear splash guard

Ø130Diameter of spindle bore 15kW spindle motor

Center of tailstock Face plate Thread dial

Drive plate Taper-turning attachment DRO

Anchor bolts Spindle center and center sleeve

Adjustable pads Foot brake(1000mm~3000mm Available)

Product model UNIT CW6163E CW6263E CW6180E CW6280E CW61100E CW62100E specification Max. swing diameter over bed mm Ø630 Ø800 Ø1000 Max.swing diameter over cross slide mm Ø350 Ø480 Ø710 Max.swing diameter in gap mm — Ø800 — Ø1000 — Ø1230 Length in gap mm — 350 — 350 — 350 Max. workpiece length mm 1000/1500/2000/3000/4000/5000/6000 Max. cutting length CW61xxx mm 850/1350/1850/2850/3850/4850/5850 CW62xxx 600/1100/1600/2600/3600/4600/5600 Spindle spindle nose C11 *D11 Spindle bore mm Ø100(C11)(Allowable bar diameter≤Ø98)

*Ø105(D11)(Allowable bar diameter≤Ø103)

opt:Ø130(Allowable bar diameter≤Ø128)Chuck size mm Ø315 Ø400 Ø400 Taper of spindle bore Metric 120(1:20)

Opt:Spindle bore Ø130- Metric 140(1:20)Max.Spindle torque Nm 2400 Spindle speed ranges rpm 7.5-1000(18 speeds) Spindle centre height mm 315 400 515 Spindle motor power 11kw/1460rpm(50HZ) Opt:15kw/1460rpm(50HZ) Tailstock Diameter of tailstock quill mm Ø100 Travel of tailstock quill mm 250 Taper of tailstock quill No.6 MT Feeds&Threads (metric screw *inch screw) Longitudinal feed metric screw mm/r 64 Speeds 1/1 0.1-1.52 ; 16/1 1.6-24.3 inch screw in/r 64 Speeds *1/1 0.0019〜0.0612 ; *16/1 0.0305-0.98 Cross feed 1/2 times of the longitudinal feed Metric threads mm 0.5〜240 (52 Kinds)

*1-256 (57 Kinds)1-240 (50 Kinds)

*1-256 (57 Kinds)0.5〜240 (52 Kinds)

*1-256 (57 Kinds)Modular threads mm 0.5 〜120 (53 Kinds) *0.5 〜128 (57 Kinds) Inch threads TPI 28-1(34 Kinds)

*32〜1/16(67 Kinds)14-1(26 Kinds)

*32-1/16(67 Kinds)28-1(34 Kinds)

*32-1/16(67 Kinds)Diametral pitch threads DP 28-1(24 Kinds) *32〜1/8(57 Kinds) Tool post Max.tool shank size mm 30X30 Travel of top slide mm 200 Swivel angle of top slide ±90° machine dimensions

(L*W*H)mm 3180X1340X1830(1000) 3630X1340X1830 (1500) 4230X1340X1830(2000) 5130X1340X1830(3000) 6040X1430X1830(4000) 7120X1430X1830(5000) 8240X1430X1830(6000) 3180X1380X1830(1000) 3630X1380X1830(1500) 4230X1380X1830 (2000) 5130X1380X1830 (3000) 6040X1470X1830 (4000) 7120X1470X1830 (5000) 8240X1470X1830(6000) 3180X1460X1830(1000) 3630X1460X1830 (1500) 4230X1460X1830(2000) 5130X1460X1830(3000) 6040X1550X1830 (4000) 7120X1550X1830(5000) 8240X1550X1830(6000) Machine weight CW61xxx kg 3900/4200/4500/5000/

5800/6500/73004100/4400/4700/5200/

6500/7200/77004350/4650/4950/5450/

6800/7300CW62xxx 4050/4350/4650/5150/

5950/6650/74504250/4550/4850/5350/

6600/7300/78504500/4800/5100/5600/

6950/7450