- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

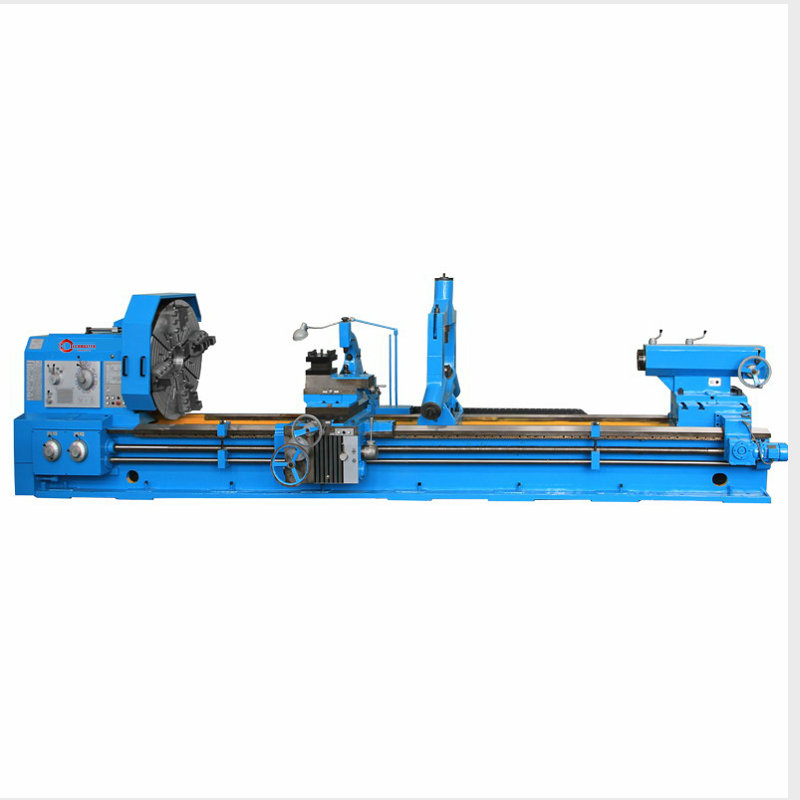

CW6163B/80B/94B Swing Dia.630MM-940MM(1.5t) Manual Semi Automatic Conventional Horizontal Lathe MachineYou are here: Home » Products » TURNING » HEAVY DUTY HORIZONTAL LATHE » CW6163B/80B/94B Swing Dia.630MM-940MM(1.5t) Manual Semi Automatic Conventional Horizontal Lathe MachineCW6163B/80B/94B Swing Dia.630MM-940MM(1.5t) Manual Semi Automatic Conventional Horizontal Lathe Machine

Availability: Quantity: -

Swing Dia.630MM-940MM(1.5t) Manual Semi Automatic Conventional Horizontal Lathe Machine

General manual machine description

This series of lathes can be used for a variety of turning work, such as turning inside and outside cylindrical surface, conical surface, and other turning surface, face, but also processing a variety of commonly used threads - such as metric, inch, modulus, diameter thread, , Hinge, tapping, tipping trunking and so on. Machine round car specimen, the roundness error is not greater than 0.01mm (the maximum diameter of the bed is greater than 800 when the 0.02), cylindrical error in the 300mm measurement length of not more than 0.04mm. High torsion-resistant flat bed, high-quality cast iron carefully manufactured, and induction on the rail surface quenching precision treatment, bed width 550mm; by the sticky PTFE conductive rails composed of flexible rails wear, vibration, precision retention Good; spindle with three support structure, high rigidity, high precision, can be strong cutting. Spindle through the hole for the Ф100mm large hole; 18 wide speed range, you can choose a more reasonable speed; can be directly turning metric and inch thread; slide box has a fast moving body.

ITEM UNIT CW6163B/CW6263B CW6180B/CW6280B CW6194B/CW6294B CAPACITIES Swing over bed mm 630 800 940 Swing over carriage mm 350 520 660 Max.length of workpiece mm 750 1000 1500 2000 3000 4000 5000 6000 8000 10000 Max.turning length mm 600 850 1350 1850 2850 3850 4850 5850 7850 9850 Swing over gap mm 830 1000 1140 Effective widthof gap mm 300 Pan of guideway mm 550 SPINDLE Spindle nose C11 Spindle bore mm 100 Taper hole of spindle 1:20/120 Range of spindle speeds r/min 7.5~1000 6~800 6~800 No.of spindle speeds 18 FEED Longitudinal and cross r/min 64;0.1~24.32 Cross/long longitudinal feed 1/2 Screw pitch of leadscrew mm 12 No. and range of metric thread mm 50;1~240 No. and range of inch thread 26;14~1 No. and range of module thread mm 53;0.5~120 No. and range of dia. thread 24;28~1 Rapid traverse speed mm/min 4000 TURRET Max.travel of cross slide mm 440 540 570 Max.travel of top slide mm 200 Section of tool shank mm 32(192x192) TAILSTOCK Dia. of tailstock mm 100 Travel of tailstock quill mm 250 Taper hole of tailstock quill mores 5 OTHERS Main motor power kw 11 Length mm 2958 3275 3725 4225 5225 6275 7355 8355 10275 12275 Width mm 1393 1473 1430 Height mm 1537 1622 1690 High precision heavy duty metal lathe price

MODEL Unit CW6163B CW6263B CW6180B CW6280B CW6194B CW6294B Swing over bed mm 630 800 940 Swing over carriage mm 350 520 660 Maximum length of workpiece mm 750/1000/1500/

2000/3000/4000/750/1000/1500/

2000/3000/4000/750/1000/1500/

2000/3000/4000/5000/6000/7000

/8000/9000/100005000/6000/7000/

8000/9000/100005000/6000/7000

/8000/9000/10000Maximum turning length mm 600/850/1350/

1850/2850/3850/600/850/1350/1850/

2850/3850/4850600/850/1350/1850/

2850/3850/48504850/5850/6850/

7885/8850/9850/5850/6850/7885

/8850/9850/5850/6850/7885/

8850/9850Swing over gap mm 830 1000 1140 Effective width of gap mm 300 300 300 Pan of guideway mm 550 550 550 Spindle nose C11 C11 C11 Spindle bore mm 100 100 100 Taper hole of spindle 1:20/120 1:20/120 1:20/120 Range of spindle speeds r/min 7.5-1000 6-800 6-800 Number of spindle speeds 18 18 18 Longitudinal and cross r/min 64;0.1-24.32 64;0.1-24.32 64;0.1-24.32 Cross-to-long longitudinal feed rate 1.0/2.0 1.0/2.0 1.0/2.0 Screw pitch of leadscrew mm 12 12 12 Number and range of metric thread mm 50;1-240 50;1-240 50;1-240 Number and range of inch thread 26;14-1 26;14-1 26;14-1 Number and range of module thread mm 53;0.5-120 53;0.5-120 53;0.5-120 Number and range of diametrical pitch thread 24;28-1 24;28-1 24;28-1 Rapid traverse speed of carriage mm/min 4000 4000 4000 Max.travel of cross slide mm 440 540 570 Max.travel of top slide mm 200 200 200 Section of tool shank mm 32 32 32 Diameter of tailstock quill mm 100 100 100 Travel of tailstock quill mm 250 250 250 Taper hole of tailstock quill Morse 5 Morse 5 Morse 5 Main motor power kw 11 11 11 Machine mass kg 3200/3400/3700/

4200/4700/5800/3400/3600/3900/

4400/4900/6000/3900/4100/4400/

4900/5400/6500/6800/7800/8800/

9800/10800/118007000/8000/9000/

10000/11000/120007500/8500/9500/10500/

11500/12500Length mm 2958/3275/3725/4225

/5225/6275/2958/3275/3725/4225/

5225/6275/2958/3275/3725/4225

/5225/6275/7355/8355/9275/

11275/122757355/8355/9275/

11275/122757355/8355/9275/

11275/12275Width mm 1393 1473 1430 Height mm 1537 1622 1690

heavy duty manual lathe machine for metal Feature

1.The side wall of bed is constructed with coublerib plates.and the shape of internal ribs is of box type and bevel ribs combination.The rigidity is higher than that of ordinary lathes.The precision is stable.And these lathes can carry out strong force cutting.

2.On apron,there is a device,operated by a single lever,used for rapid traverse of the carriage.Spindle's braking and rotating directionchange is controlled by hydraulic system,or by hand operation,all to user's choice.

3.The saddle guide way is glued by "TSF" soft belt wear resisting materials.

4.On user's demand,we can equip the lathe with automatic feeding mechanism.The top slide can be used independently for turning of short cone.In combination with longitudinal feeding,it can also turn long taper surface.

heavy duty manual lathe machine for metal Stand Accessories32 3-Jaw chuck

20~170mm Steady rest

20~100mm Following rest

Dead center.

General manual machine description

This series of lathes can be used for a variety of turning work, such as turning inside and outside cylindrical surface, conical surface, and other turning surface, face, but also processing a variety of commonly used threads - such as metric, inch, modulus, diameter thread, , Hinge, tapping, tipping trunking and so on. Machine round car specimen, the roundness error is not greater than 0.01mm (the maximum diameter of the bed is greater than 800 when the 0.02), cylindrical error in the 300mm measurement length of not more than 0.04mm. High torsion-resistant flat bed, high-quality cast iron carefully manufactured, and induction on the rail surface quenching precision treatment, bed width 550mm; by the sticky PTFE conductive rails composed of flexible rails wear, vibration, precision retention Good; spindle with three support structure, high rigidity, high precision, can be strong cutting. Spindle through the hole for the Ф100mm large hole; 18 wide speed range, you can choose a more reasonable speed; can be directly turning metric and inch thread; slide box has a fast moving body.

ITEM UNIT CW6163B/CW6263B CW6180B/CW6280B CW6194B/CW6294B CAPACITIES Swing over bed mm 630 800 940 Swing over carriage mm 350 520 660 Max.length of workpiece mm 750 1000 1500 2000 3000 4000 5000 6000 8000 10000 Max.turning length mm 600 850 1350 1850 2850 3850 4850 5850 7850 9850 Swing over gap mm 830 1000 1140 Effective widthof gap mm 300 Pan of guideway mm 550 SPINDLE Spindle nose C11 Spindle bore mm 100 Taper hole of spindle 1:20/120 Range of spindle speeds r/min 7.5~1000 6~800 6~800 No.of spindle speeds 18 FEED Longitudinal and cross r/min 64;0.1~24.32 Cross/long longitudinal feed 1/2 Screw pitch of leadscrew mm 12 No. and range of metric thread mm 50;1~240 No. and range of inch thread 26;14~1 No. and range of module thread mm 53;0.5~120 No. and range of dia. thread 24;28~1 Rapid traverse speed mm/min 4000 TURRET Max.travel of cross slide mm 440 540 570 Max.travel of top slide mm 200 Section of tool shank mm 32(192x192) TAILSTOCK Dia. of tailstock mm 100 Travel of tailstock quill mm 250 Taper hole of tailstock quill mores 5 OTHERS Main motor power kw 11 Length mm 2958 3275 3725 4225 5225 6275 7355 8355 10275 12275 Width mm 1393 1473 1430 Height mm 1537 1622 1690 High precision heavy duty metal lathe price

MODEL Unit CW6163B CW6263B CW6180B CW6280B CW6194B CW6294B Swing over bed mm 630 800 940 Swing over carriage mm 350 520 660 Maximum length of workpiece mm 750/1000/1500/

2000/3000/4000/750/1000/1500/

2000/3000/4000/750/1000/1500/

2000/3000/4000/5000/6000/7000

/8000/9000/100005000/6000/7000/

8000/9000/100005000/6000/7000

/8000/9000/10000Maximum turning length mm 600/850/1350/

1850/2850/3850/600/850/1350/1850/

2850/3850/4850600/850/1350/1850/

2850/3850/48504850/5850/6850/

7885/8850/9850/5850/6850/7885

/8850/9850/5850/6850/7885/

8850/9850Swing over gap mm 830 1000 1140 Effective width of gap mm 300 300 300 Pan of guideway mm 550 550 550 Spindle nose C11 C11 C11 Spindle bore mm 100 100 100 Taper hole of spindle 1:20/120 1:20/120 1:20/120 Range of spindle speeds r/min 7.5-1000 6-800 6-800 Number of spindle speeds 18 18 18 Longitudinal and cross r/min 64;0.1-24.32 64;0.1-24.32 64;0.1-24.32 Cross-to-long longitudinal feed rate 1.0/2.0 1.0/2.0 1.0/2.0 Screw pitch of leadscrew mm 12 12 12 Number and range of metric thread mm 50;1-240 50;1-240 50;1-240 Number and range of inch thread 26;14-1 26;14-1 26;14-1 Number and range of module thread mm 53;0.5-120 53;0.5-120 53;0.5-120 Number and range of diametrical pitch thread 24;28-1 24;28-1 24;28-1 Rapid traverse speed of carriage mm/min 4000 4000 4000 Max.travel of cross slide mm 440 540 570 Max.travel of top slide mm 200 200 200 Section of tool shank mm 32 32 32 Diameter of tailstock quill mm 100 100 100 Travel of tailstock quill mm 250 250 250 Taper hole of tailstock quill Morse 5 Morse 5 Morse 5 Main motor power kw 11 11 11 Machine mass kg 3200/3400/3700/

4200/4700/5800/3400/3600/3900/

4400/4900/6000/3900/4100/4400/

4900/5400/6500/6800/7800/8800/

9800/10800/118007000/8000/9000/

10000/11000/120007500/8500/9500/10500/

11500/12500Length mm 2958/3275/3725/4225

/5225/6275/2958/3275/3725/4225/

5225/6275/2958/3275/3725/4225

/5225/6275/7355/8355/9275/

11275/122757355/8355/9275/

11275/122757355/8355/9275/

11275/12275Width mm 1393 1473 1430 Height mm 1537 1622 1690

heavy duty manual lathe machine for metal Feature

1.The side wall of bed is constructed with coublerib plates.and the shape of internal ribs is of box type and bevel ribs combination.The rigidity is higher than that of ordinary lathes.The precision is stable.And these lathes can carry out strong force cutting.

2.On apron,there is a device,operated by a single lever,used for rapid traverse of the carriage.Spindle's braking and rotating directionchange is controlled by hydraulic system,or by hand operation,all to user's choice.

3.The saddle guide way is glued by "TSF" soft belt wear resisting materials.

4.On user's demand,we can equip the lathe with automatic feeding mechanism.The top slide can be used independently for turning of short cone.In combination with longitudinal feeding,it can also turn long taper surface.

heavy duty manual lathe machine for metal Stand Accessories32 3-Jaw chuck

20~170mm Steady rest

20~100mm Following rest

Dead center.