- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

Engineer Series C8 Lathe-

Engineer Series C8 Lathe

- Medium capacity, high quality lathe suitable for workshop or school use

- 6-step belt drive gives a spindle speed range of 100-2,500rpm

- 735W 1ph induction motor provides plenty of power

- Metric and imperial thread cutting, simple gearbox settings

- Integral splash guard and drip tray, and optional floor stand

- Full range of accessories available, tooling, steadies etc

- Converts to a multi-purpose machine with the milling attachment

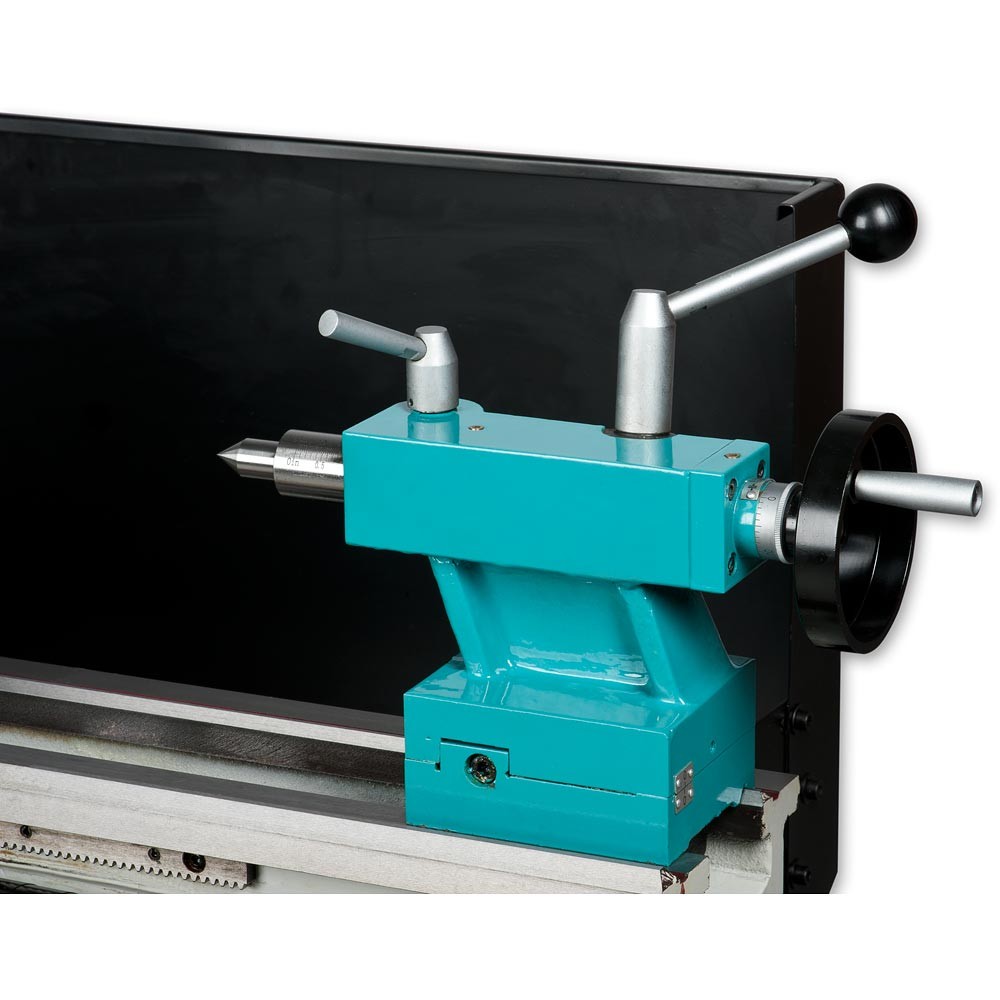

This is a very solid medium sized bench lathe with many modern conveniences. As you would expect, the bed is made from high tensile cast iron with induction hardened slideways. Power is provided by a robust 735W 1ph induction motor including a reversing function. A 6-step belt drive system provides speeds from 125-2,000rpm. A 130mm 3-jaw self centring chuck is provided, driven by a 54mm diameter spindle supported on adjustable tapered roller bearings, with a 25mm through bore. The carriage is powered in both axis, giving faster, smoother cuts and smoother facing; a clever interlock prevents accidental engagement, plus an overload clutch is fitted to the carriage drive shaft. Selection of either feed speeds or thread pitches is via a simple twin gearbox arrangement, the conversion between metric or imperial threads being just one gear wheel change. There is also a tumbler gear set-up to allow LH threading. The tailstock has cam locking and taper spindle offset; the tailstock ram lead screw is also very accurately made. All the controls are grouped on the front face of the headstock, with the spindle speed being clearly indicated. A locking "E" stop switch and an interlocked steel chuck guard are included. A 4-way tool post is fitted which will take tooling up to 16mm shank size. A swarf tray is also included, helping to keep the workshop clean.

This is the basic version of this lathe, which can be tailored to your requirements with many optional accessories such as a floor stand, 2-axis digital read-out (DRO), quick change tool post, faceplates, steadies etc. Another very useful component is a powered milling attachment, which bolts to the rear of the bed and plugs into its own power outlet. Based on the SX2 mill, this creates a very versatile machining centre.

For those looking for a more complete and advanced lathe (with a high torque variable speed motor, stand, DRO, coolant system and work lamp), please look at the SC8-AX2 505114. This is a completely factory made machine with integrated wiring etc. and may be well suited to the education sector or small component making.

Specification

Centre Height 140mm Cross Slide Travel 155mm Distance Between Centres 750mm Max Diameter over Bed 280mm Model C8 Nett Weight 185kg Overall L x W x H 1,500 x 750 x 630mm Power 735W (230V) Rating Engineer Spindle Bore 25mm Spindle Speed 100-2,500 Thread Pitch Range 0.25-2.5mm (14 thread pitches), 12-96tpi (9 thread pitches). Top Slide Travel 80mm Headstock Taper 4MT Tailstock Taper 2MT

- Medium capacity, high quality lathe suitable for workshop or school use

- 6-step belt drive gives a spindle speed range of 100-2,500rpm

- 735W 1ph induction motor provides plenty of power

- Metric and imperial thread cutting, simple gearbox settings

- Integral splash guard and drip tray, and optional floor stand

- Full range of accessories available, tooling, steadies etc

- Converts to a multi-purpose machine with the milling attachment

This is a very solid medium sized bench lathe with many modern conveniences. As you would expect, the bed is made from high tensile cast iron with induction hardened slideways. Power is provided by a robust 735W 1ph induction motor including a reversing function. A 6-step belt drive system provides speeds from 125-2,000rpm. A 130mm 3-jaw self centring chuck is provided, driven by a 54mm diameter spindle supported on adjustable tapered roller bearings, with a 25mm through bore. The carriage is powered in both axis, giving faster, smoother cuts and smoother facing; a clever interlock prevents accidental engagement, plus an overload clutch is fitted to the carriage drive shaft. Selection of either feed speeds or thread pitches is via a simple twin gearbox arrangement, the conversion between metric or imperial threads being just one gear wheel change. There is also a tumbler gear set-up to allow LH threading. The tailstock has cam locking and taper spindle offset; the tailstock ram lead screw is also very accurately made. All the controls are grouped on the front face of the headstock, with the spindle speed being clearly indicated. A locking "E" stop switch and an interlocked steel chuck guard are included. A 4-way tool post is fitted which will take tooling up to 16mm shank size. A swarf tray is also included, helping to keep the workshop clean.

This is the basic version of this lathe, which can be tailored to your requirements with many optional accessories such as a floor stand, 2-axis digital read-out (DRO), quick change tool post, faceplates, steadies etc. Another very useful component is a powered milling attachment, which bolts to the rear of the bed and plugs into its own power outlet. Based on the SX2 mill, this creates a very versatile machining centre.

For those looking for a more complete and advanced lathe (with a high torque variable speed motor, stand, DRO, coolant system and work lamp), please look at the SC8-AX2 505114. This is a completely factory made machine with integrated wiring etc. and may be well suited to the education sector or small component making.

Specification

Centre Height 140mm Cross Slide Travel 155mm Distance Between Centres 750mm Max Diameter over Bed 280mm Model C8 Nett Weight 185kg Overall L x W x H 1,500 x 750 x 630mm Power 735W (230V) Rating Engineer Spindle Bore 25mm Spindle Speed 100-2,500 Thread Pitch Range 0.25-2.5mm (14 thread pitches), 12-96tpi (9 thread pitches). Top Slide Travel 80mm Headstock Taper 4MT Tailstock Taper 2MT