English

- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

Engineer Series Runmaster 330 x 1000 LatheYou are here: Home » Products » TURNING » PROFESSIONAL ENGINE LATHE » Engineer Series Runmaster 330 x 1000 Lathe-

Engineer Series Runmaster 330 x 1000 Lathe

- Precision floor standing lathe built to a very high standard

- 2-axis DRO display system included

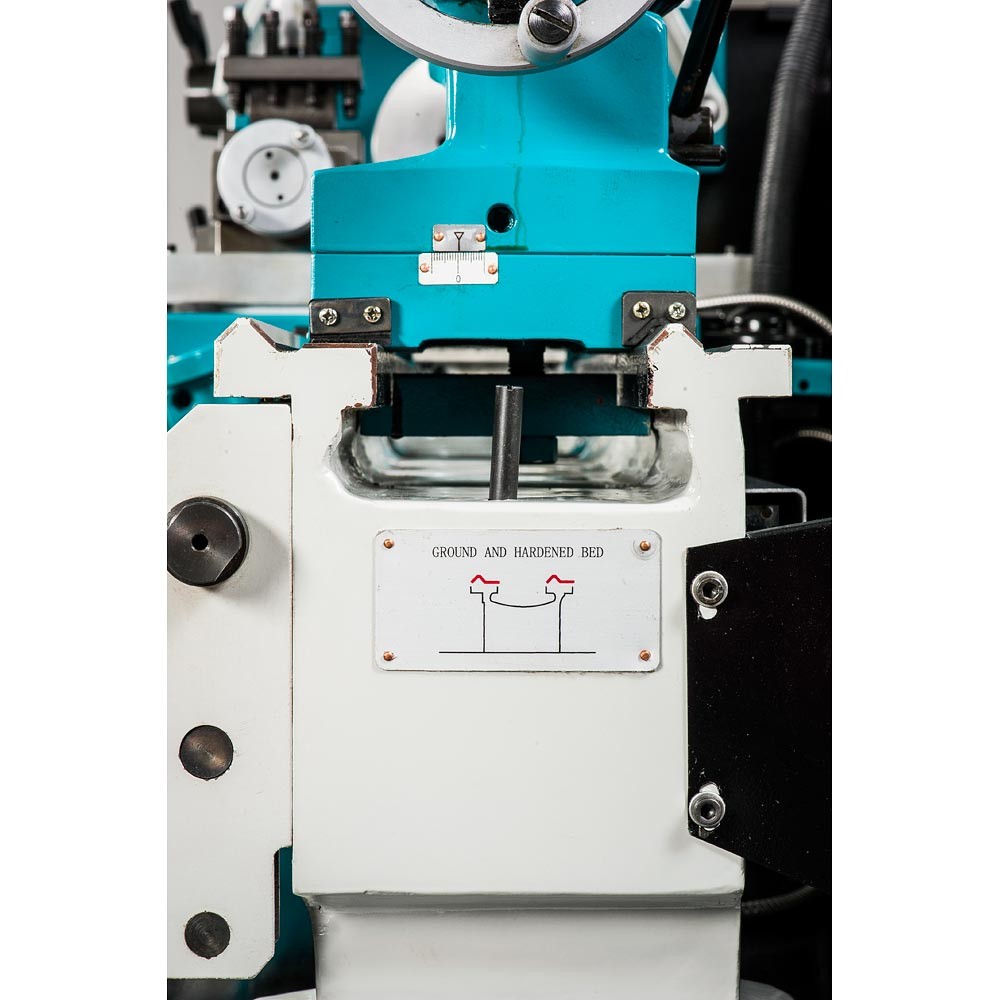

- Deeply webbed, cast iron bed with ground, induction hardened slideways

- 8 speed 70-2,000 rpm (230V) or 16 speeds 35-2,000 rpm (415V)

- Large taper roller spindle bearings for precision running

- 3mm leadscrew with a choice of 32 ratios in metric graduations

- Comprehensive range of accessories included as standard

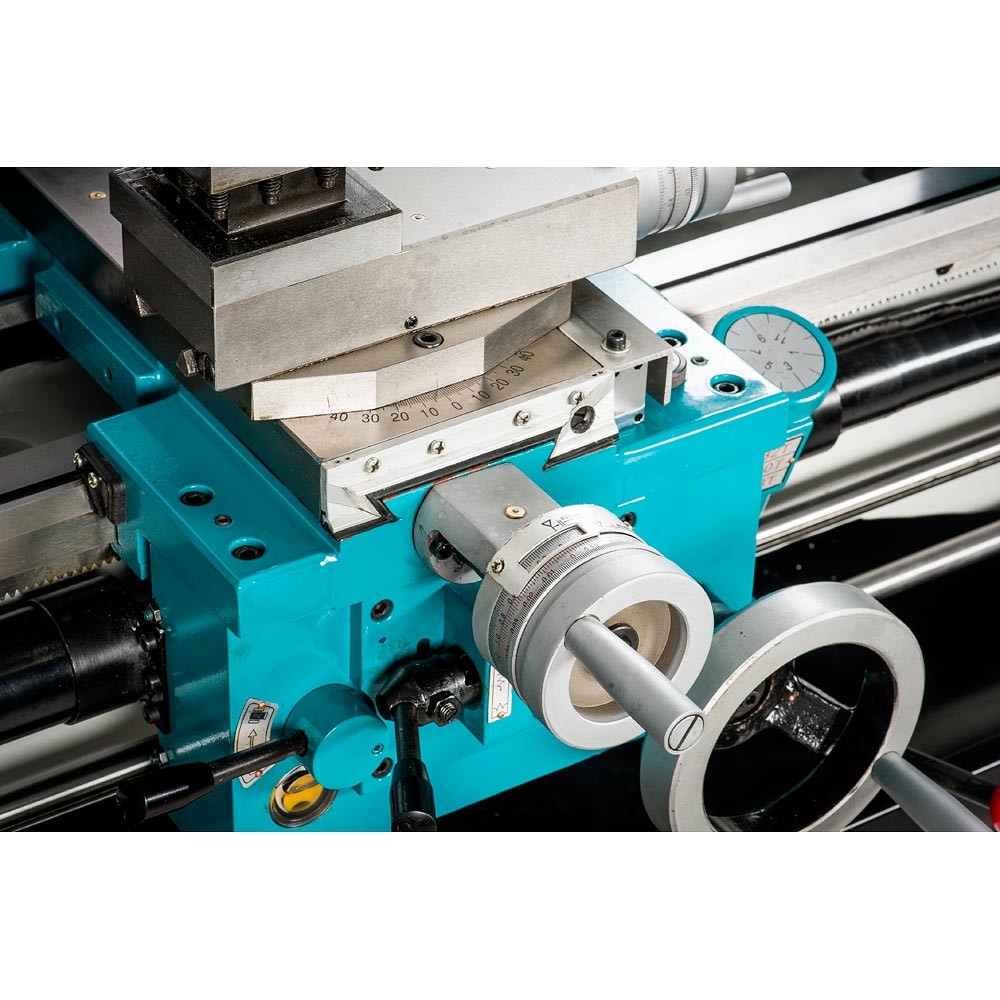

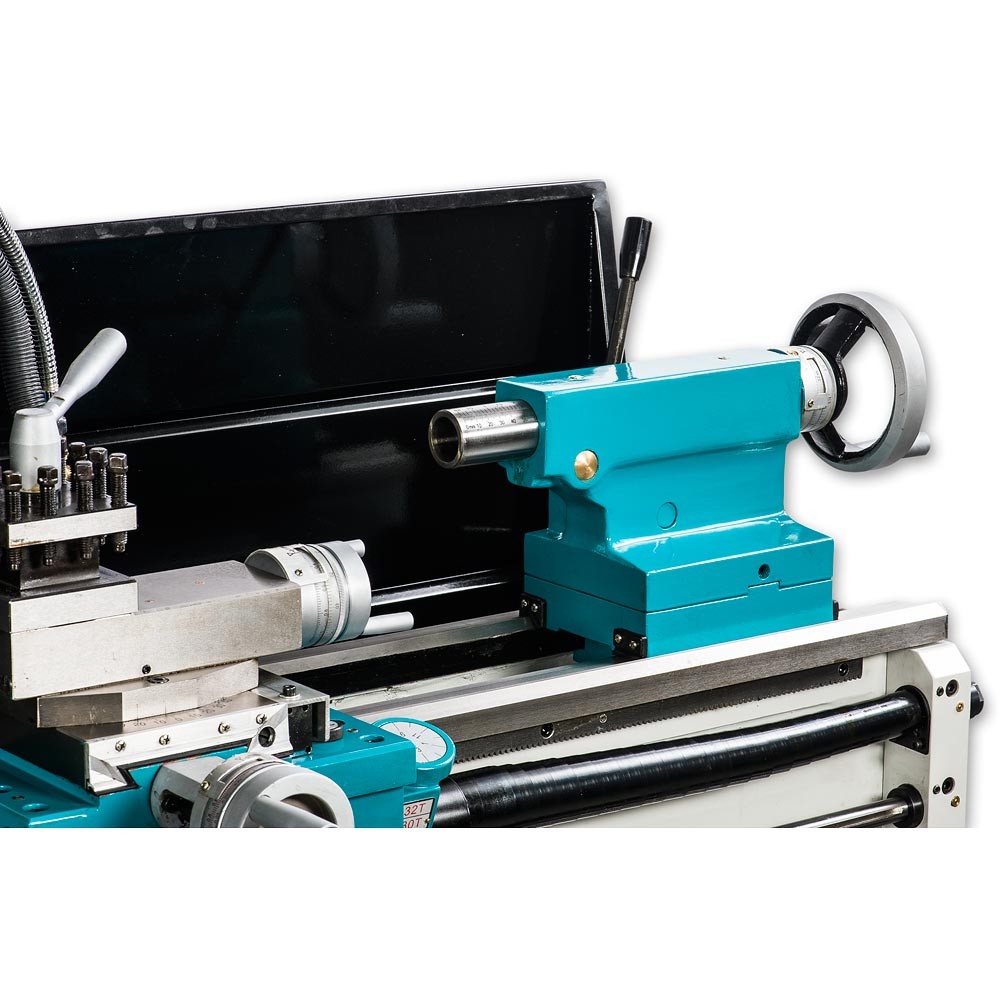

This is a high speed precision lathe built to a very high standard and based around a deep webbed, cast iron bed with ground, induction hardened slideways providing great rigidity and strength. It is powered by a 2.2kW(415V or 230V) motor driving a headstock gearbox providing 8 speeds from 70-2000 rpm (230V) or 16 speeds, 35-2000 rpm (415V) through hardened gears. The spindle is carried on large taper roller bearings, has a D1-4 chuck mount and has a 38mm through bore with a 5MT in the nose. A very rigid carriage has power drive on the compound axis and is fitted with a 4-way tool post that can take tooling up to 16mm in size. The leadscrew pitch is 3mm and is driven by a gear box offering a choice of 32 ratios for general turning, and is easily reversible. The change wheel set provided offers a good range of thread cutting choices, 26 metric, 0.4-7mm pitch and 34 imperial, 4-56tpi. A thread dial indicator with 3 ratios is provided to assist in re-engaging the leadscrew in the correct position. There is a 2-axis DRO system included, featuring metric and imperial displays and linear compensation to enable a totally accurate measurement. The tailstock has a quick action camlock, a taper turning transverse adjustment, a fine pitch leadscrew for the barrel and a 4MT bore. The machine has 24V switch gear, a chuck guard interlock switch and a foot operated brake for safe operation. It comes with a comprehensive range of standard accessories including work lamp, rear splash back guard, cabinet stand with lockable cupboard, change wheel set, coolant pump and equipment, 150mm 3-jaw chuck with internal and external jaws, 200mm 4-jaw independent chuck, 250mm faceplate, live and dead centres, 5-3MT reduction sleeve, travelling steady, fixed steady and a toolbox with comprehensive tool kit plus spare brake shoes and operating cable. This machine is very suitable for educational establishments, maintenance workshops and small production workshops, and will prove to be a pleasure to use. N.B. Will require a 16A supply.

Specification

Centre Height 166mm Cross Slide Travel 165mm Distance Between Centres 1,000mm Height Over Cross Slide 99mm Leadscrew Pitch 3mm Max Diameter over Bed 330mm Model Runmaster 330RR X 1000 Nett Weight 610kg Overall L x W x H 1,940 x 755 x 1,238mm Power 2.2kW Rating Engineer Spindle Bore 38mm Spindle Speed 35-2000rpm (16) Thread Pitch Range (26) 0.4-7mm / (34) 4-56 tpi Top Slide Travel 165mm Headstock Taper 5MT Tailstock Taper 4MT

- Precision floor standing lathe built to a very high standard

- 2-axis DRO display system included

- Deeply webbed, cast iron bed with ground, induction hardened slideways

- 8 speed 70-2,000 rpm (230V) or 16 speeds 35-2,000 rpm (415V)

- Large taper roller spindle bearings for precision running

- 3mm leadscrew with a choice of 32 ratios in metric graduations

- Comprehensive range of accessories included as standard

This is a high speed precision lathe built to a very high standard and based around a deep webbed, cast iron bed with ground, induction hardened slideways providing great rigidity and strength. It is powered by a 2.2kW(415V or 230V) motor driving a headstock gearbox providing 8 speeds from 70-2000 rpm (230V) or 16 speeds, 35-2000 rpm (415V) through hardened gears. The spindle is carried on large taper roller bearings, has a D1-4 chuck mount and has a 38mm through bore with a 5MT in the nose. A very rigid carriage has power drive on the compound axis and is fitted with a 4-way tool post that can take tooling up to 16mm in size. The leadscrew pitch is 3mm and is driven by a gear box offering a choice of 32 ratios for general turning, and is easily reversible. The change wheel set provided offers a good range of thread cutting choices, 26 metric, 0.4-7mm pitch and 34 imperial, 4-56tpi. A thread dial indicator with 3 ratios is provided to assist in re-engaging the leadscrew in the correct position. There is a 2-axis DRO system included, featuring metric and imperial displays and linear compensation to enable a totally accurate measurement. The tailstock has a quick action camlock, a taper turning transverse adjustment, a fine pitch leadscrew for the barrel and a 4MT bore. The machine has 24V switch gear, a chuck guard interlock switch and a foot operated brake for safe operation. It comes with a comprehensive range of standard accessories including work lamp, rear splash back guard, cabinet stand with lockable cupboard, change wheel set, coolant pump and equipment, 150mm 3-jaw chuck with internal and external jaws, 200mm 4-jaw independent chuck, 250mm faceplate, live and dead centres, 5-3MT reduction sleeve, travelling steady, fixed steady and a toolbox with comprehensive tool kit plus spare brake shoes and operating cable. This machine is very suitable for educational establishments, maintenance workshops and small production workshops, and will prove to be a pleasure to use. N.B. Will require a 16A supply.

Specification

Centre Height 166mm Cross Slide Travel 165mm Distance Between Centres 1,000mm Height Over Cross Slide 99mm Leadscrew Pitch 3mm Max Diameter over Bed 330mm Model Runmaster 330RR X 1000 Nett Weight 610kg Overall L x W x H 1,940 x 755 x 1,238mm Power 2.2kW Rating Engineer Spindle Bore 38mm Spindle Speed 35-2000rpm (16) Thread Pitch Range (26) 0.4-7mm / (34) 4-56 tpi Top Slide Travel 165mm Headstock Taper 5MT Tailstock Taper 4MT