- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

Engineer Series SC8-AX2 Lathe-

Engineer Series SC8-AX2 Lathe

- Medium capacity, high quality lathe suitable for workshop or school use

- Electronically variable spindle speed range of 100-2,500rpm

- 1,500W high torque, brushless motor provides plenty of power

- Metric and imperial thread cutting, simple gearbox settings

- Floor stand, 2-axis DRO, coolant and work light included

- Full range of accessories available, tooling, steadies etc.

- Converts to a multi-purpose machine with optional milling attachment

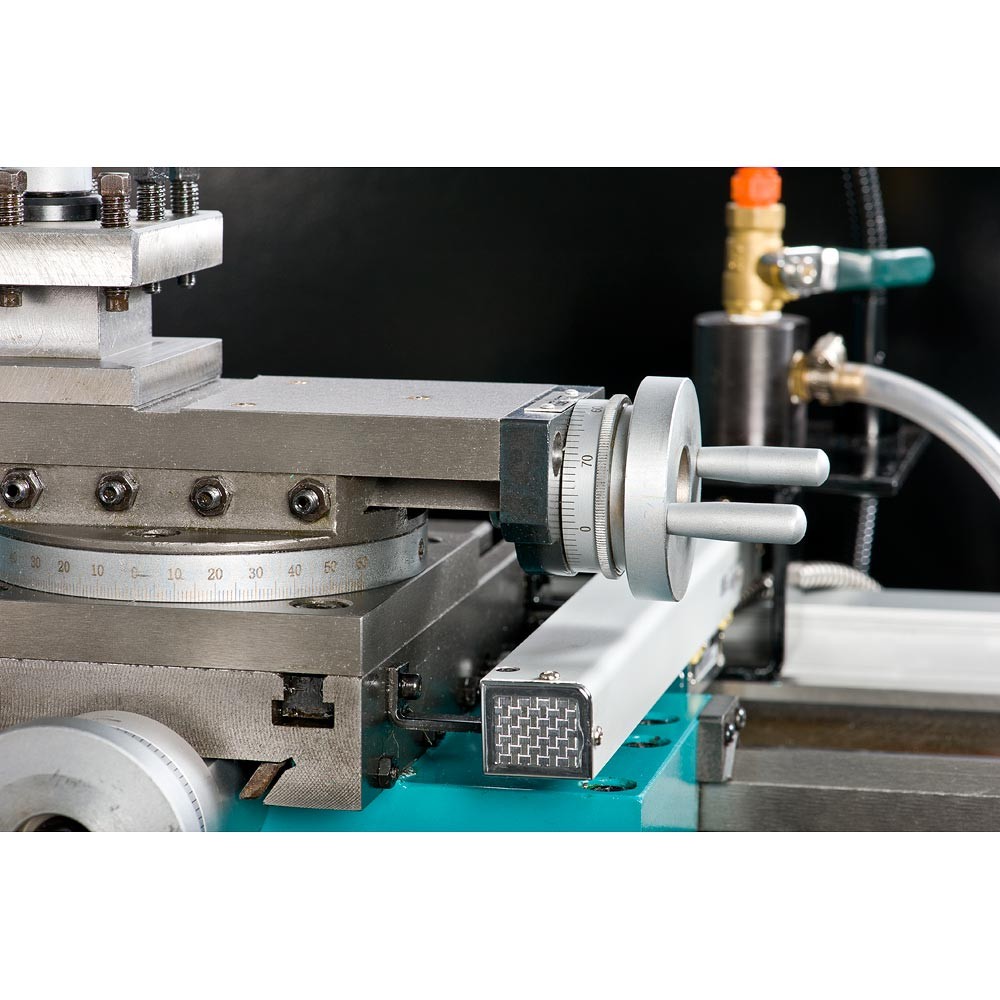

This is the high specification version of this very fine medium sized bench lathe which has many modern conveniences. As you would expect, the bed is made from high tensile cast iron with induction hardened slideways. Power is provided by a 1,500W brushless DC high torque motor, with all functions controlled by a push button panel. A 150mm 3-jaw self centring chuck is provided, driven by a 54mm diameter spindle supported on adjustable tapered roller bearings, with a 25mm through bore. The carriage is powered in both axis, a clever interlock prevents accidental engagement, plus an overload clutch is fitted to the carriage drive shaft. Selection of either feed speeds or thread pitches is via a simple twin gearbox arrangement, the conversion between metric or imperial threads being just one gear wheel change. There is also a tumbler gear set-up to allow LH threading. The tailstock has cam locking and spindle taper offset; the tailstock ram leadscrew is very accurately made. All the controls are grouped on the front face of the headstock, with the spindle speed being clearly indicated. A locking "E" stop switch and an interlocked steel chuck guard are included. A 4-way tool post is fitted which will take tooling up to 16mm shank size.

This version is built onto the floor stand and is fitted with a 2-axis digital read-out, a built-in coolant system and a work light, resulting in a ready-to-use (bar cleaning and adjusting) lathe with the most useful options factory fitted. All of the other accessories for the SC8-AX1 model are available, such as fixed and travelling steadies, self powered milling attachment, faceplate, 4-jaw chuck, collet chuck etc. This is a most comprehensively specified lathe, suitable for serious model engineering, small component making and educational use.

Axminster Engineer Series SC8-AX2 Lathe

- Medium capacity, high quality lathe suitable for workshop or school use

- Electronically variable spindle speed range of 100-2,500rpm

- 1,500W high torque, brushless motor provides plenty of power

- Metric and imperial thread cutting, simple gearbox settings

- Floor stand, 2-axis DRO, coolant and work light included

- Full range of accessories available, tooling, steadies etc.

- Converts to a multi-purpose machine with optional milling attachment

£3,851.96 (£3,209.97 Ex. VAT)In stock - heavy goods delivery within 21 working days

Learn how it worksCollect in store, we'll confirm your reservation within 1 hour.

Check stock at your local storeWe Also Recommend

- Show More

Frequently Bought Together

- This product: Axminster Engineer Series SC8-AX2 Lathe - £3,851.96

- Axminster Engineer Series SC8 4-Jaw130mm Self Centring Chuck - £186.96

In Detail

Engineer Classification & 3 Year GuaranteeThis is the high specification version of this very fine medium sized bench lathe which has many modern conveniences. As you would expect, the bed is made from high tensile cast iron with induction hardened slideways. Power is provided by a 1,500W brushless DC high torque motor, with all functions controlled by a push button panel. A 150mm 3-jaw self centring chuck is provided, driven by a 54mm diameter spindle supported on adjustable tapered roller bearings, with a 25mm through bore. The carriage is powered in both axis, a clever interlock prevents accidental engagement, plus an overload clutch is fitted to the carriage drive shaft. Selection of either feed speeds or thread pitches is via a simple twin gearbox arrangement, the conversion between metric or imperial threads being just one gear wheel change. There is also a tumbler gear set-up to allow LH threading. The tailstock has cam locking and spindle taper offset; the tailstock ram leadscrew is very accurately made. All the controls are grouped on the front face of the headstock, with the spindle speed being clearly indicated. A locking "E" stop switch and an interlocked steel chuck guard are included. A 4-way tool post is fitted which will take tooling up to 16mm shank size.

This version is built onto the floor stand and is fitted with a 2-axis digital read-out, a built-in coolant system and a work light, resulting in a ready-to-use (bar cleaning and adjusting) lathe with the most useful options factory fitted. All of the other accessories for the SC8-AX1 model are available, such as fixed and travelling steadies, self powered milling attachment, faceplate, 4-jaw chuck, collet chuck etc. This is a most comprehensively specified lathe, suitable for serious model engineering, small component making and educational use.

Information Downloads

Specification

Centre Height 140mm Cross Slide Travel 155mm Distance Between Centres 750mm Max Diameter over Bed 280mm Model SC8 Nett Weight 310kg Overall L x W x H 1,500 x 750 x 630mm Power 1,500W (230V) Rating Engineer Spindle Bore 25mm Spindle Speed 100-2,500 Thread Pitch Range 0.25-2.5mm (14 thread pitches), 12-96tpi (9 thread pitches). Top Slide Travel 80mm Headstock Taper 4MT Tailstock Taper 2MT

- Medium capacity, high quality lathe suitable for workshop or school use

- Electronically variable spindle speed range of 100-2,500rpm

- 1,500W high torque, brushless motor provides plenty of power

- Metric and imperial thread cutting, simple gearbox settings

- Floor stand, 2-axis DRO, coolant and work light included

- Full range of accessories available, tooling, steadies etc.

- Converts to a multi-purpose machine with optional milling attachment

This is the high specification version of this very fine medium sized bench lathe which has many modern conveniences. As you would expect, the bed is made from high tensile cast iron with induction hardened slideways. Power is provided by a 1,500W brushless DC high torque motor, with all functions controlled by a push button panel. A 150mm 3-jaw self centring chuck is provided, driven by a 54mm diameter spindle supported on adjustable tapered roller bearings, with a 25mm through bore. The carriage is powered in both axis, a clever interlock prevents accidental engagement, plus an overload clutch is fitted to the carriage drive shaft. Selection of either feed speeds or thread pitches is via a simple twin gearbox arrangement, the conversion between metric or imperial threads being just one gear wheel change. There is also a tumbler gear set-up to allow LH threading. The tailstock has cam locking and spindle taper offset; the tailstock ram leadscrew is very accurately made. All the controls are grouped on the front face of the headstock, with the spindle speed being clearly indicated. A locking "E" stop switch and an interlocked steel chuck guard are included. A 4-way tool post is fitted which will take tooling up to 16mm shank size.

This version is built onto the floor stand and is fitted with a 2-axis digital read-out, a built-in coolant system and a work light, resulting in a ready-to-use (bar cleaning and adjusting) lathe with the most useful options factory fitted. All of the other accessories for the SC8-AX1 model are available, such as fixed and travelling steadies, self powered milling attachment, faceplate, 4-jaw chuck, collet chuck etc. This is a most comprehensively specified lathe, suitable for serious model engineering, small component making and educational use.

Axminster Engineer Series SC8-AX2 Lathe

- Medium capacity, high quality lathe suitable for workshop or school use

- Electronically variable spindle speed range of 100-2,500rpm

- 1,500W high torque, brushless motor provides plenty of power

- Metric and imperial thread cutting, simple gearbox settings

- Floor stand, 2-axis DRO, coolant and work light included

- Full range of accessories available, tooling, steadies etc.

- Converts to a multi-purpose machine with optional milling attachment

£3,851.96 (£3,209.97 Ex. VAT)In stock - heavy goods delivery within 21 working days

Learn how it worksCollect in store, we'll confirm your reservation within 1 hour.

Check stock at your local storeWe Also Recommend

- Show More

Frequently Bought Together

- This product: Axminster Engineer Series SC8-AX2 Lathe - £3,851.96

- Axminster Engineer Series SC8 4-Jaw130mm Self Centring Chuck - £186.96

In Detail

Engineer Classification & 3 Year GuaranteeThis is the high specification version of this very fine medium sized bench lathe which has many modern conveniences. As you would expect, the bed is made from high tensile cast iron with induction hardened slideways. Power is provided by a 1,500W brushless DC high torque motor, with all functions controlled by a push button panel. A 150mm 3-jaw self centring chuck is provided, driven by a 54mm diameter spindle supported on adjustable tapered roller bearings, with a 25mm through bore. The carriage is powered in both axis, a clever interlock prevents accidental engagement, plus an overload clutch is fitted to the carriage drive shaft. Selection of either feed speeds or thread pitches is via a simple twin gearbox arrangement, the conversion between metric or imperial threads being just one gear wheel change. There is also a tumbler gear set-up to allow LH threading. The tailstock has cam locking and spindle taper offset; the tailstock ram leadscrew is very accurately made. All the controls are grouped on the front face of the headstock, with the spindle speed being clearly indicated. A locking "E" stop switch and an interlocked steel chuck guard are included. A 4-way tool post is fitted which will take tooling up to 16mm shank size.

This version is built onto the floor stand and is fitted with a 2-axis digital read-out, a built-in coolant system and a work light, resulting in a ready-to-use (bar cleaning and adjusting) lathe with the most useful options factory fitted. All of the other accessories for the SC8-AX1 model are available, such as fixed and travelling steadies, self powered milling attachment, faceplate, 4-jaw chuck, collet chuck etc. This is a most comprehensively specified lathe, suitable for serious model engineering, small component making and educational use.

Information Downloads

Specification

Centre Height 140mm Cross Slide Travel 155mm Distance Between Centres 750mm Max Diameter over Bed 280mm Model SC8 Nett Weight 310kg Overall L x W x H 1,500 x 750 x 630mm Power 1,500W (230V) Rating Engineer Spindle Bore 25mm Spindle Speed 100-2,500 Thread Pitch Range 0.25-2.5mm (14 thread pitches), 12-96tpi (9 thread pitches). Top Slide Travel 80mm Headstock Taper 4MT Tailstock Taper 2MT