- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

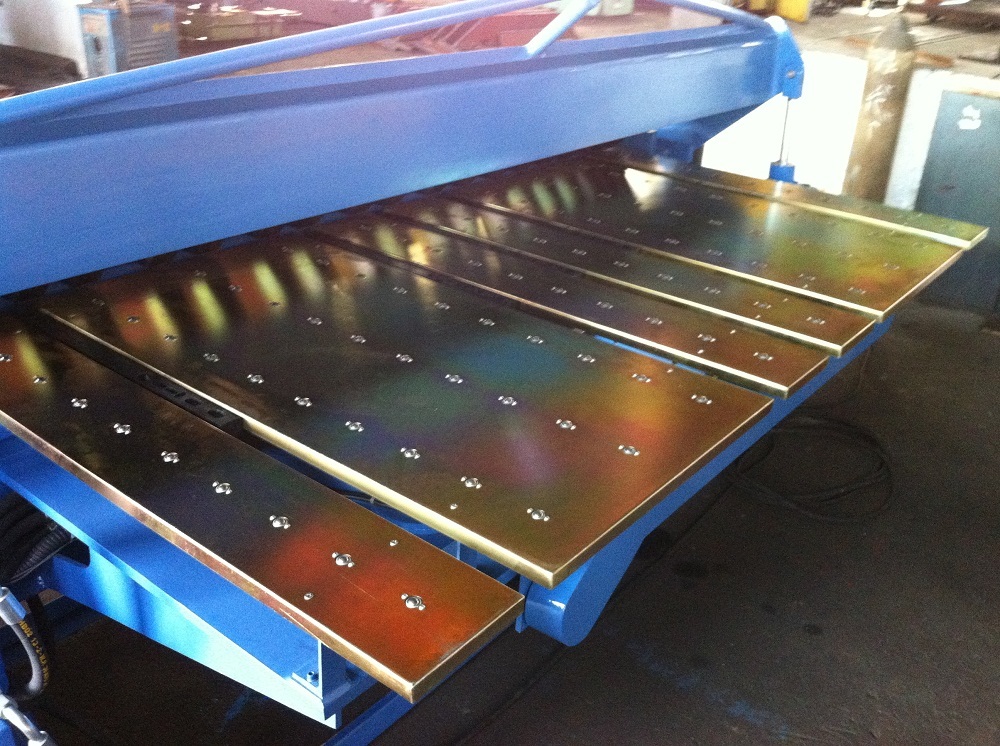

FHPB3204CNC2. Panbrake Folder. Full Hydraulic. 3200mm x 4mm, Foldmaster 2 Axis CNC GraphicalYou are here: Home » Products » METAL FORMING MACHINE » BENDING MACHINE » FHPB3204CNC2. Panbrake Folder. Full Hydraulic. 3200mm x 4mm, Foldmaster 2 Axis CNC GraphicalFHPB3204CNC2. Panbrake Folder. Full Hydraulic. 3200mm x 4mm, Foldmaster 2 Axis CNC Graphical

Quantity: -

FHPB3204CNC2. Panbrake Folder. Full Hydraulic. 3200mm x 4mm, Foldmaster 2 Axis CNC Graphical

Description

At last, a 2 Axis CNC graphical full hydraulic panbrake folder - controlling bending angle and backgauge position!

Our Australian designed & engineered Full hydraulic Panbrake will blow the competition away.

Working smarter, not harder with our CNC Foldmaster machine. Offering a smart full graphical CNC Foldmaster controller. Full CNC programming functions.

This can be used both in the single "enter angle and fold" mode, or used in a multi sequence folding and backgauge operation - Watch the video and see how easy this is.

We offer a 600mm precision ballscrew back gauge as standard however, if you require longer, we can provide these on request.

Features

❚hardened and ground fingers, perfect for all bending applications

❚hydraulically operated bending and clamping beam for efficient heavy duty operation

❚high structural rigidity from heavy plate steel box construction with continuous welded seams

❚bending beam powered by dual hydraulic cylinders

❚fully integrated and enclosed electric / hydraulic system with large oil reservoir to maintain low oil temperature

❚high load capacity dual spherical plane bearings utilized at bending beam pivots and over-centre clamp bearings

❚precise electric / hydraulic controls with manual inching of bending beam

❚utilization of easy to set micro-switches provides accurate & infinitely adjustable angle control to the folding apron

❚comprehensive equipment protection from electric and hydraulic overload systems

Hydraulic System

❚high quality componentry ensures reliable performance for years of continuous operation

❚powerful direct coupled hydraulic pump and motor provides efficient, rapid operation

❚unique electric / hydraulic control ensures safe and simple operation

Foldmaster Features

❚can be fitted to most press brakes, pan brakes & slitter folders.

❚large 15" Touch screen

❚easy Job Selection

❚select existing jobs from the library

❚jobs can be named and saved for future use. A virtually unlimited number of jobs can be saved

❚jobs open with all relevant data like bend sequence, angle corrections, which bends were done from front or rear etc. This saves lots of set-up time.

❚jobs can be linked to fold boxes easily

❚each operator can have his own password with his own job library.

Foldmaster – 5 Easy steps to put you in production in no time!

Step 1. MASTERDRAW: How easy is this!.....

Simply touch the corners on the grid to draw the box

Press OK to return to the main screen

Step 2. Simply touch on the dimension or angle of the profile on the right to edit the value on the popup keypad

Step 3. How good is this!........ See the profile on the left for easy editing….. and the folding simulation

• View the actual folding sequence simulation on the graphic of a Panbrake as you fold in real time or animation mode.

• Change folds from front to rear to optimise production.

• Step through the whole sequence without wasting time or material.

• This process can be used in minutes to assist in doing new quotes accurately

• Touch the “Automatic fold sequence” button or set the fold sequence manually simply by entering the sequence (1 2 8 7 6 5 3 4 for the example on the left).

Step 4. Enter material thickness and width.

Step 5. Start production

Technical Data Snap-Shot

❚3200mm x 4.0mm bending capacity

❚o ~ 135 bending range

❚backgauge travel length - 900mm. Position A & B

❚optional backgauge travel length to 1200mm available on request. Position A, B & C

❚shipping dimensions - 3800mm x 1650mm x 1650mm

❚power - 415V 4.0Kw

❚approx weight: 4100kg

Description

At last, a 2 Axis CNC graphical full hydraulic panbrake folder - controlling bending angle and backgauge position!

Our Australian designed & engineered Full hydraulic Panbrake will blow the competition away.

Working smarter, not harder with our CNC Foldmaster machine. Offering a smart full graphical CNC Foldmaster controller. Full CNC programming functions.

This can be used both in the single "enter angle and fold" mode, or used in a multi sequence folding and backgauge operation - Watch the video and see how easy this is.

We offer a 600mm precision ballscrew back gauge as standard however, if you require longer, we can provide these on request.

Features

❚hardened and ground fingers, perfect for all bending applications

❚hydraulically operated bending and clamping beam for efficient heavy duty operation

❚high structural rigidity from heavy plate steel box construction with continuous welded seams

❚bending beam powered by dual hydraulic cylinders

❚fully integrated and enclosed electric / hydraulic system with large oil reservoir to maintain low oil temperature

❚high load capacity dual spherical plane bearings utilized at bending beam pivots and over-centre clamp bearings

❚precise electric / hydraulic controls with manual inching of bending beam

❚utilization of easy to set micro-switches provides accurate & infinitely adjustable angle control to the folding apron

❚comprehensive equipment protection from electric and hydraulic overload systems

Hydraulic System

❚high quality componentry ensures reliable performance for years of continuous operation

❚powerful direct coupled hydraulic pump and motor provides efficient, rapid operation

❚unique electric / hydraulic control ensures safe and simple operation

Foldmaster Features

❚can be fitted to most press brakes, pan brakes & slitter folders.

❚large 15" Touch screen

❚easy Job Selection

❚select existing jobs from the library

❚jobs can be named and saved for future use. A virtually unlimited number of jobs can be saved

❚jobs open with all relevant data like bend sequence, angle corrections, which bends were done from front or rear etc. This saves lots of set-up time.

❚jobs can be linked to fold boxes easily

❚each operator can have his own password with his own job library.

Foldmaster – 5 Easy steps to put you in production in no time!

Step 1. MASTERDRAW: How easy is this!.....

Simply touch the corners on the grid to draw the box

Press OK to return to the main screen

Step 2. Simply touch on the dimension or angle of the profile on the right to edit the value on the popup keypad

Step 3. How good is this!........ See the profile on the left for easy editing….. and the folding simulation

• View the actual folding sequence simulation on the graphic of a Panbrake as you fold in real time or animation mode.

• Change folds from front to rear to optimise production.

• Step through the whole sequence without wasting time or material.

• This process can be used in minutes to assist in doing new quotes accurately

• Touch the “Automatic fold sequence” button or set the fold sequence manually simply by entering the sequence (1 2 8 7 6 5 3 4 for the example on the left).

Step 4. Enter material thickness and width.

Step 5. Start production

Technical Data Snap-Shot

❚3200mm x 4.0mm bending capacity

❚o ~ 135 bending range

❚backgauge travel length - 900mm. Position A & B

❚optional backgauge travel length to 1200mm available on request. Position A, B & C

❚shipping dimensions - 3800mm x 1650mm x 1650mm

❚power - 415V 4.0Kw

❚approx weight: 4100kg