English

- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

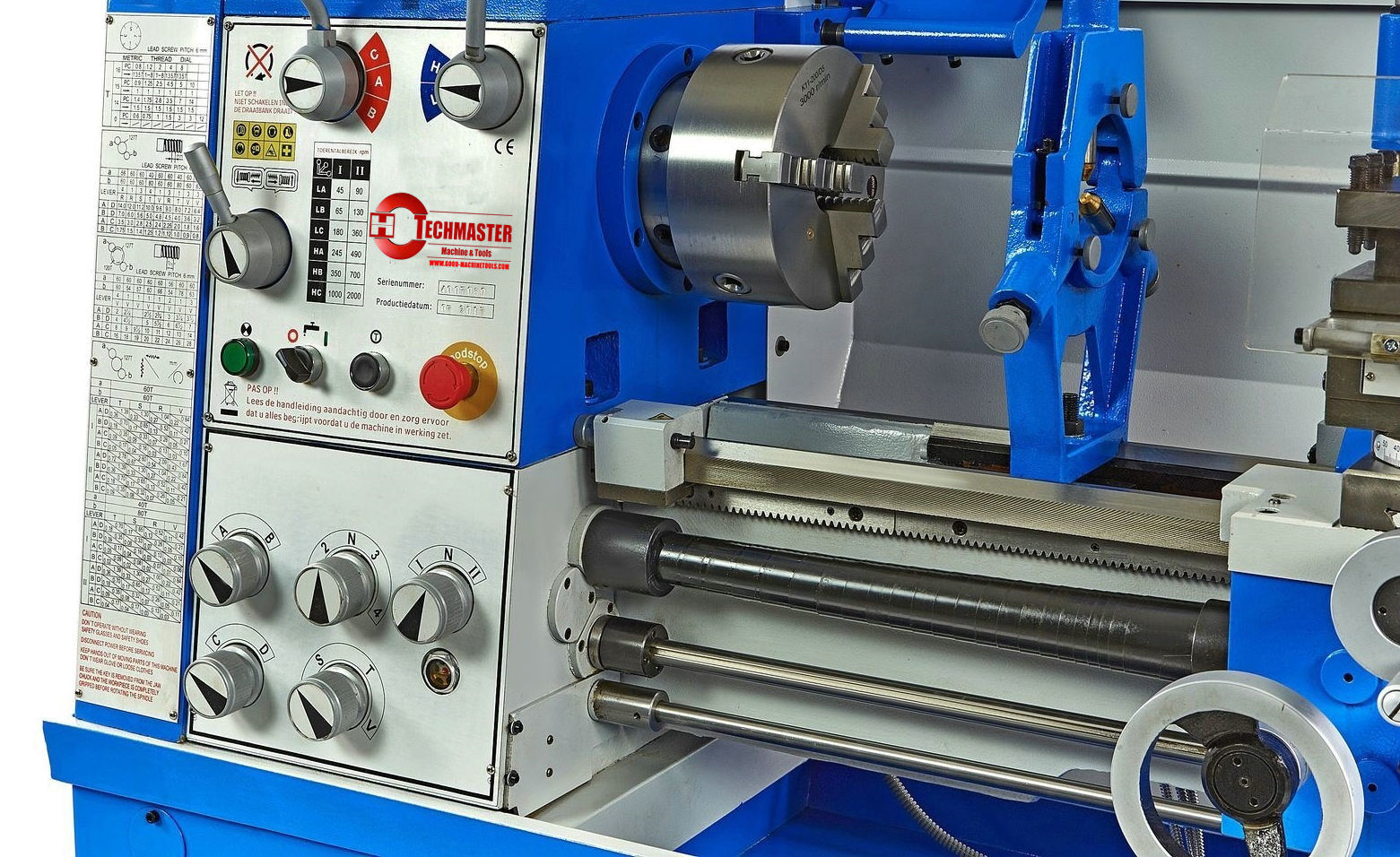

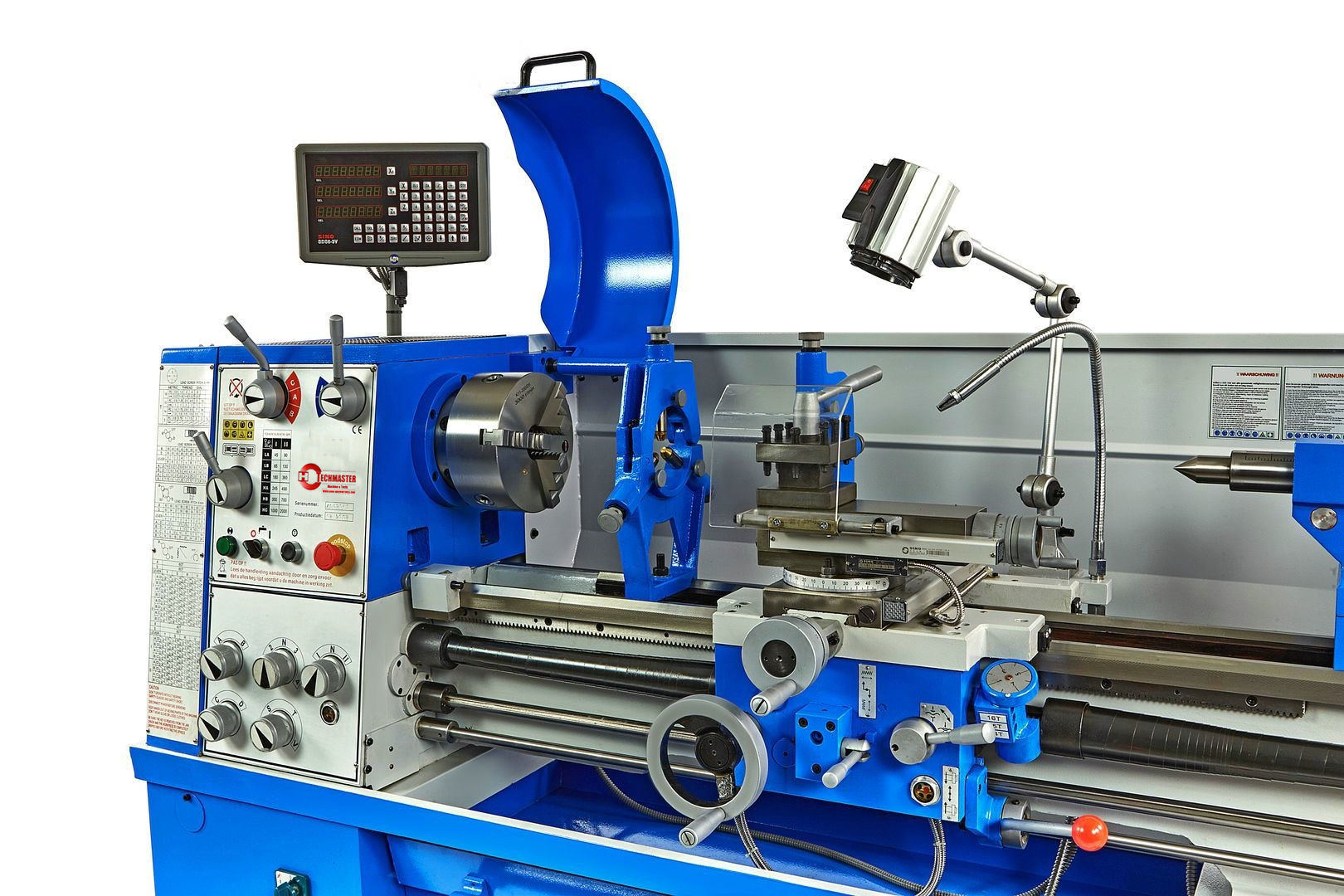

Precision Gap-Bed Metal Turning Manual Bench Lathe D400X1000You are here: Home » Products » TURNING » PROFESSIONAL ENGINE LATHE » Precision Gap-Bed Metal Turning Manual Bench Lathe D400X1000D400X1000 is a solidly constructed universal lathe, offering a wide range of applications. Features of this model include the large turning diameter of 400 mm and the 55 mm spindle bore. Its construction (design, performance, feeds etc) covers all needs for training purposes, as well as for tool shops and repair shops.

Ideal for processing of steel, non-ferrous metals and plastics

Electro-magnetic foot brake reduces downtime

Hardened and polished toothed gears also in feed drive

Practical, solid machine featuring a lead screw and feed rod

Grey cast-iron machine bed, inductively hardened and precisely polished

State-of-the-art spindle bedding with high-quality, angular ball bearings

Machine base in heavy cast iron construction

Tailstock can be adjusted ± 5 mm for taper turning

Ideal for technical colleges, repair shops and training purposes

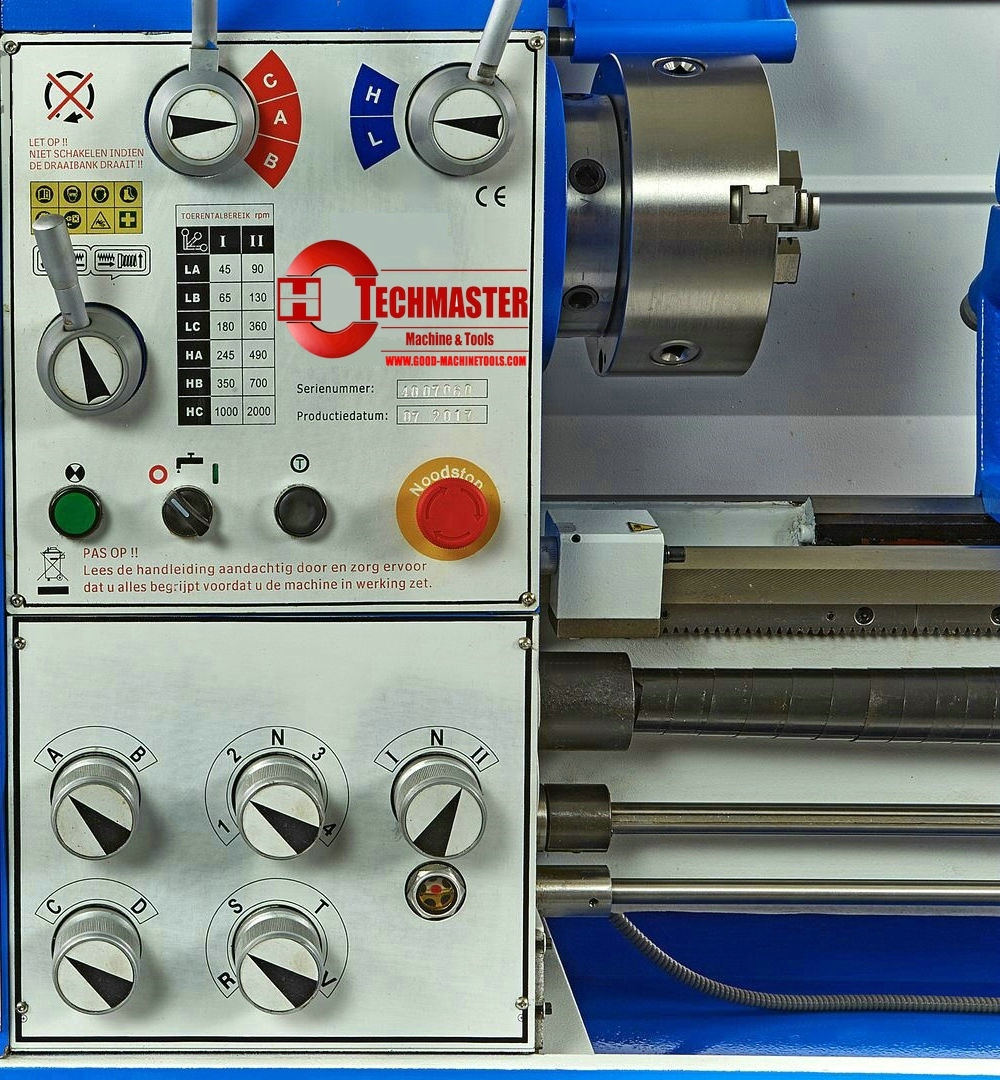

Easy, smooth and precisely adjustable speed and feed settings

Pull-out chip tray allows for minimum space requirements

Removable bridge for processing of work pieces with a large diameter

Optimal price-benefit ratio, modern design

Serially equipped with slip clutch

Big bore spindle Φ 52mm Camlock D1-5 with Φ 200mm 3 jaw direct mounting chuck mounted

Spindle runs in adjustable precision tapered roller bearings in headstock

Gapped bedway for clamping workpiece of big diameter

Cast iron bed with double Vee guides hardened and precision ground

Oil bath lubrication spindle headstock, feed box and apron box

Shift gear system to change feed direction

Interlock feature between feed shaft and lead screw shaft

Adjustable tapered gibs for all sliding guides

Double speed motor provides wide spindle speeds 45- 2000 rpm

Top slide swivels ± 60º , Tailstock offset for taper turning

Electro-magnetic foot brake providing quick and safe rapid braking of spindle

Open type chip pan easily to remove chips away

Jog button for easy gear engagement in spindle stock

Emergency stop button mounted on the front of head stock for quick and safety power off

Extra safety micro-switch on/off for belt change over or gear change over for threading

Chuck Guard Safety Protection with micro switch

Standard Accessories:

Direct mounting 3 Jaw Self-centering Chuck Φ 200mm

Direct mounting 4 Jaw Independent Chuck Φ 200mm

Face Plate Φ 320mm

Steady and Follow Rests

Halogen Work Lamp

Coolant System

Foot Braking System,

4 Way Tool Holder

Change Gears Set

Threading Dial

Tool Box with Operation Tools

Reduction Sleeves MT6/MT4

Fixed Centers MT4 x 2PCS

Cabinet Stand with Chip Tray and Splash Guard

Optional Accessories:

3 Jaw Self-centering Chuck Φ 250mm with flange

4 Jaw Independent Chuck Φ 250mm with flange

Tool Post Guard Protection with micro switch

Lead Screw Shaft Cover Protection

Precision Roller Center of Heavy Duty MT4#

Piston Type of Quick Change Tool Post 250-300 Set

With 3 Tool Holders 20mm + 1 Tool/Bar Holder 20/16mm

Distance between centers 1000 mm Center height 200 mm Swing over bed 400 mm Swing over gap 560 mm Swing over cross slide 240 mm Bed width 210 mm Spindle bore 55 mm Spindle nose fixture DIN 55029, D1-5 Speed range (12) 45 - 2000 rpm Longitudinal feed (27) 0,06 - 2,78 mm/rev. Cross feed (22) 0,01 - 0,72 mm/rev. Metric thread (36) 0,8 - 14 mm Inch thread (30) 2 - 28 threads/1" Diameter of tailstock sleeve 45 mm Travel of tailstock sleeve 100 mm Taper of tailstock sleeve MT 4 Motor power 2,0 kW / 2,4 kW Machine dimension (W x D x H) 1860 x 800 x 1600 mm Weight approx. 810 kg

D400X1000 is a solidly constructed universal lathe, offering a wide range of applications. Features of this model include the large turning diameter of 400 mm and the 55 mm spindle bore. Its construction (design, performance, feeds etc) covers all needs for training purposes, as well as for tool shops and repair shops.

Ideal for processing of steel, non-ferrous metals and plastics

Electro-magnetic foot brake reduces downtime

Hardened and polished toothed gears also in feed drive

Practical, solid machine featuring a lead screw and feed rod

Grey cast-iron machine bed, inductively hardened and precisely polished

State-of-the-art spindle bedding with high-quality, angular ball bearings

Machine base in heavy cast iron construction

Tailstock can be adjusted ± 5 mm for taper turning

Ideal for technical colleges, repair shops and training purposes

Easy, smooth and precisely adjustable speed and feed settings

Pull-out chip tray allows for minimum space requirements

Removable bridge for processing of work pieces with a large diameter

Optimal price-benefit ratio, modern design

Serially equipped with slip clutch

Big bore spindle Φ 52mm Camlock D1-5 with Φ 200mm 3 jaw direct mounting chuck mounted

Spindle runs in adjustable precision tapered roller bearings in headstock

Gapped bedway for clamping workpiece of big diameter

Cast iron bed with double Vee guides hardened and precision ground

Oil bath lubrication spindle headstock, feed box and apron box

Shift gear system to change feed direction

Interlock feature between feed shaft and lead screw shaft

Adjustable tapered gibs for all sliding guides

Double speed motor provides wide spindle speeds 45- 2000 rpm

Top slide swivels ± 60º , Tailstock offset for taper turning

Electro-magnetic foot brake providing quick and safe rapid braking of spindle

Open type chip pan easily to remove chips away

Jog button for easy gear engagement in spindle stock

Emergency stop button mounted on the front of head stock for quick and safety power off

Extra safety micro-switch on/off for belt change over or gear change over for threading

Chuck Guard Safety Protection with micro switch

Standard Accessories:

Direct mounting 3 Jaw Self-centering Chuck Φ 200mm

Direct mounting 4 Jaw Independent Chuck Φ 200mm

Face Plate Φ 320mm

Steady and Follow Rests

Halogen Work Lamp

Coolant System

Foot Braking System,

4 Way Tool Holder

Change Gears Set

Threading Dial

Tool Box with Operation Tools

Reduction Sleeves MT6/MT4

Fixed Centers MT4 x 2PCS

Cabinet Stand with Chip Tray and Splash Guard

Optional Accessories:

3 Jaw Self-centering Chuck Φ 250mm with flange

4 Jaw Independent Chuck Φ 250mm with flange

Tool Post Guard Protection with micro switch

Lead Screw Shaft Cover Protection

Precision Roller Center of Heavy Duty MT4#

Piston Type of Quick Change Tool Post 250-300 Set

With 3 Tool Holders 20mm + 1 Tool/Bar Holder 20/16mm

Distance between centers 1000 mm Center height 200 mm Swing over bed 400 mm Swing over gap 560 mm Swing over cross slide 240 mm Bed width 210 mm Spindle bore 55 mm Spindle nose fixture DIN 55029, D1-5 Speed range (12) 45 - 2000 rpm Longitudinal feed (27) 0,06 - 2,78 mm/rev. Cross feed (22) 0,01 - 0,72 mm/rev. Metric thread (36) 0,8 - 14 mm Inch thread (30) 2 - 28 threads/1" Diameter of tailstock sleeve 45 mm Travel of tailstock sleeve 100 mm Taper of tailstock sleeve MT 4 Motor power 2,0 kW / 2,4 kW Machine dimension (W x D x H) 1860 x 800 x 1600 mm Weight approx. 810 kg