- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

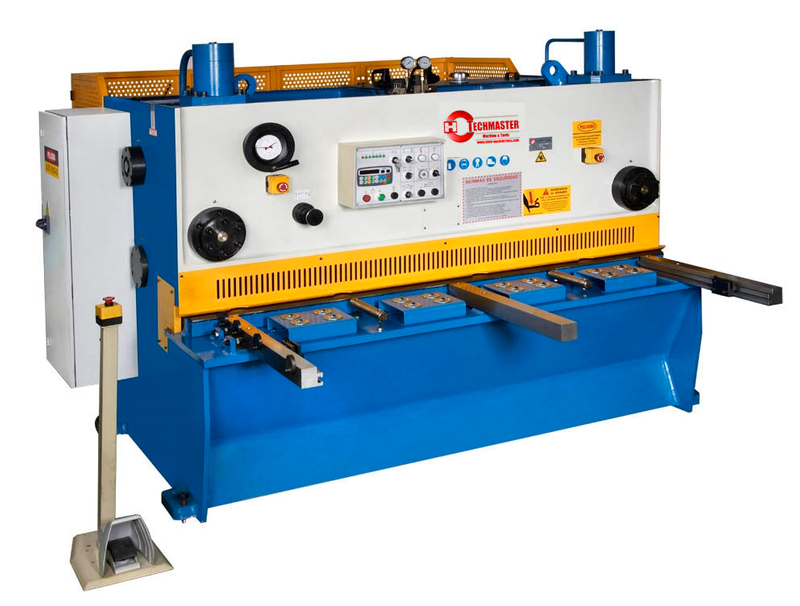

QC11Y-6X3100 HYDRAULIC SHEARYou are here: Home » Products » METAL FORMING MACHINE » SHEARING MACHINE » QC11Y-6X3100 HYDRAULIC SHEARDetails of QC11Y-6x3100 High quality Hydraulic shear machine

(1)this machine belongs to second generation of hydraulic shear, with advanced integrated hydraulic system with an excellent reliability and easy for maintenance.

(2)the shearing angle can not be changed due to the series cylinder.

(3)the rolling guide with 3-point support and improves the shearing quality.

(4)the power storage device returns steadily and quickly.

(5)the rectangular monoblock blades featuring long life with 4 cutting edges.

(6)rapidly, accurately and conveniently adjusting the blade clearance with the handwheel.

(7)the adjustable rake angle can minimize plate deformation.

(8)as the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed. Shearing in sections (adjust the time displayed on liquid crystal), shadow-line cutting.

(9)counter for the motorized back gauge, very accurate and convenient.

(10)rolling plate-support of the machine, this can reduce the hurt of the plates and reduce the conflict force.Technical parameters:

Model

Mild Steel

(450MPA)

Cutting Length

(mm)

Depth Of Throat (mm)

Back Gauge Range(mm)

Rake Angle Adjustment

Strokes Per Minute

Main Motor

(kw)

4×2000

4

2000

80

750

0.5°~2°

14

5.5

4×2500

4

2000

80

750

0.5°~2°

14

5.5

6×2500

6

2500

80

750

0.5°~1°30′

14

7.5

6×3200

6

3200

80

750

0.5°~1°30′

12

7.5

6×4000

6

4000

80

750

0.5°~1°30′

10

7.5

6×5000

6

5000

80

750

0.5°~1°30′

8

7.5

6×6000

6

6000

80

750

0.5°~1°30′

8

7.5

8×2500

8

6000

80

750

0.5°~2°

14

7.5

8×3200

8

3200

80

750

0.5°~2°

12

7.5

8×4000

8

4000

80

750

0.5°~2°

10

7.5

8×5000

8

5000

80

750

0.5°~2°

7

15

8×6000

8

6000

100

750

0.5°~2°

7

15

10×2500

10

2500

100

750

0.5°~2°30′

10

15

10×3200

10

3200

100

750

0.5°~2°30′

8

15

10×4000

10

4000

100

750

0.5°~2°30′

6

15

10×5000

10

5000

100

750

0.5°~2°30′

5

15

10×6000

10

6000

100

750

0.5°~2°30′

5

15

12×2500

12

2500

100

750

0.5°~2°30′

10

15

12×3200

12

3200

100

750

0.5°~2°30′

8

15

12×4000

12

4000

100

750

0.5°~2°30′

5

15

12×5000

12

5000

100

750

0.5°~2°30′

5

30

12×6000

12

6000

100

750

0.5°~2°30′

5

30

16×2500

16

2500

100

750

0.5°~2°30′

8

15

16×3200

16

3200

100

750

0.5°~2°30′

7

15

16×4000

16

4000

100

750

0.5°~2°30′

6

15

16×5000

16

5000

100

750

0.5°~3°

5

22

16×6000

16

6000

100

750

0.5°~3°

5

37

20×2500

20

2500

100

750

0.5°~3°

6

22

20×3200

20

3200

120

750

0.5°~3°

5

30

20×4000

20

4000

120

750

0.5°~3°

4

30

20×5000

20

5000

120

750

0.5°~3°

4

37

20×6000

20

6000

120

750

0.5°~3°

5

37

25×2500

25

2500

120

750

0.5°~3.5°

5

37

25×3200

25

3200

120

750

0.5°~3.5°

5

37

25×4000

25

4000

120

750

0.5°~3.5°

4

37

30×2500

30

2500

120

750

0.5°~3.5°

4

37

30×3200

30

3200

120

750

1°~3.5°

3

37

40×2500

40

2500

80

750

1°~4°

4

37×2

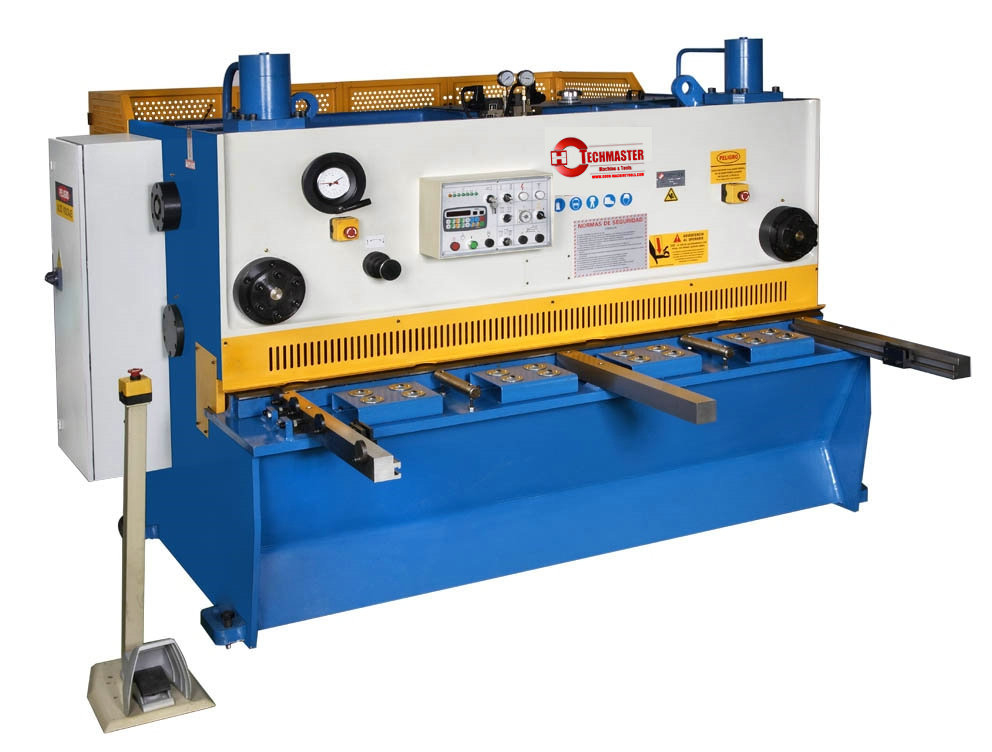

Details of QC11Y-6x3100 High quality Hydraulic shear machine

(1)this machine belongs to second generation of hydraulic shear, with advanced integrated hydraulic system with an excellent reliability and easy for maintenance.

(2)the shearing angle can not be changed due to the series cylinder.

(3)the rolling guide with 3-point support and improves the shearing quality.

(4)the power storage device returns steadily and quickly.

(5)the rectangular monoblock blades featuring long life with 4 cutting edges.

(6)rapidly, accurately and conveniently adjusting the blade clearance with the handwheel.

(7)the adjustable rake angle can minimize plate deformation.

(8)as the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed. Shearing in sections (adjust the time displayed on liquid crystal), shadow-line cutting.

(9)counter for the motorized back gauge, very accurate and convenient.

(10)rolling plate-support of the machine, this can reduce the hurt of the plates and reduce the conflict force.Technical parameters:

Model

Mild Steel

(450MPA)

Cutting Length

(mm)

Depth Of Throat (mm)

Back Gauge Range(mm)

Rake Angle Adjustment

Strokes Per Minute

Main Motor

(kw)

4×2000

4

2000

80

750

0.5°~2°

14

5.5

4×2500

4

2000

80

750

0.5°~2°

14

5.5

6×2500

6

2500

80

750

0.5°~1°30′

14

7.5

6×3200

6

3200

80

750

0.5°~1°30′

12

7.5

6×4000

6

4000

80

750

0.5°~1°30′

10

7.5

6×5000

6

5000

80

750

0.5°~1°30′

8

7.5

6×6000

6

6000

80

750

0.5°~1°30′

8

7.5

8×2500

8

6000

80

750

0.5°~2°

14

7.5

8×3200

8

3200

80

750

0.5°~2°

12

7.5

8×4000

8

4000

80

750

0.5°~2°

10

7.5

8×5000

8

5000

80

750

0.5°~2°

7

15

8×6000

8

6000

100

750

0.5°~2°

7

15

10×2500

10

2500

100

750

0.5°~2°30′

10

15

10×3200

10

3200

100

750

0.5°~2°30′

8

15

10×4000

10

4000

100

750

0.5°~2°30′

6

15

10×5000

10

5000

100

750

0.5°~2°30′

5

15

10×6000

10

6000

100

750

0.5°~2°30′

5

15

12×2500

12

2500

100

750

0.5°~2°30′

10

15

12×3200

12

3200

100

750

0.5°~2°30′

8

15

12×4000

12

4000

100

750

0.5°~2°30′

5

15

12×5000

12

5000

100

750

0.5°~2°30′

5

30

12×6000

12

6000

100

750

0.5°~2°30′

5

30

16×2500

16

2500

100

750

0.5°~2°30′

8

15

16×3200

16

3200

100

750

0.5°~2°30′

7

15

16×4000

16

4000

100

750

0.5°~2°30′

6

15

16×5000

16

5000

100

750

0.5°~3°

5

22

16×6000

16

6000

100

750

0.5°~3°

5

37

20×2500

20

2500

100

750

0.5°~3°

6

22

20×3200

20

3200

120

750

0.5°~3°

5

30

20×4000

20

4000

120

750

0.5°~3°

4

30

20×5000

20

5000

120

750

0.5°~3°

4

37

20×6000

20

6000

120

750

0.5°~3°

5

37

25×2500

25

2500

120

750

0.5°~3.5°

5

37

25×3200

25

3200

120

750

0.5°~3.5°

5

37

25×4000

25

4000

120

750

0.5°~3.5°

4

37

30×2500

30

2500

120

750

0.5°~3.5°

4

37

30×3200

30

3200

120

750

1°~3.5°

3

37

40×2500

40

2500

80

750

1°~4°

4

37×2