- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

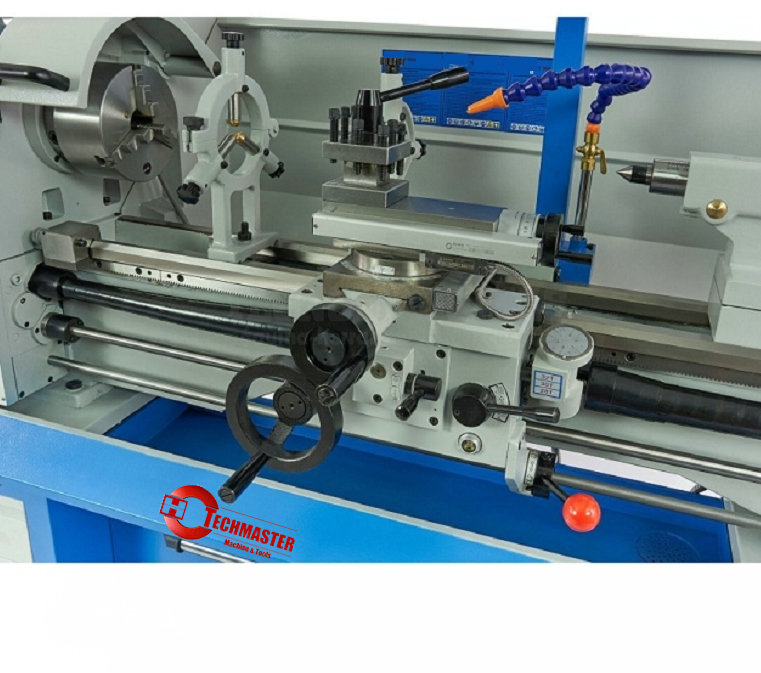

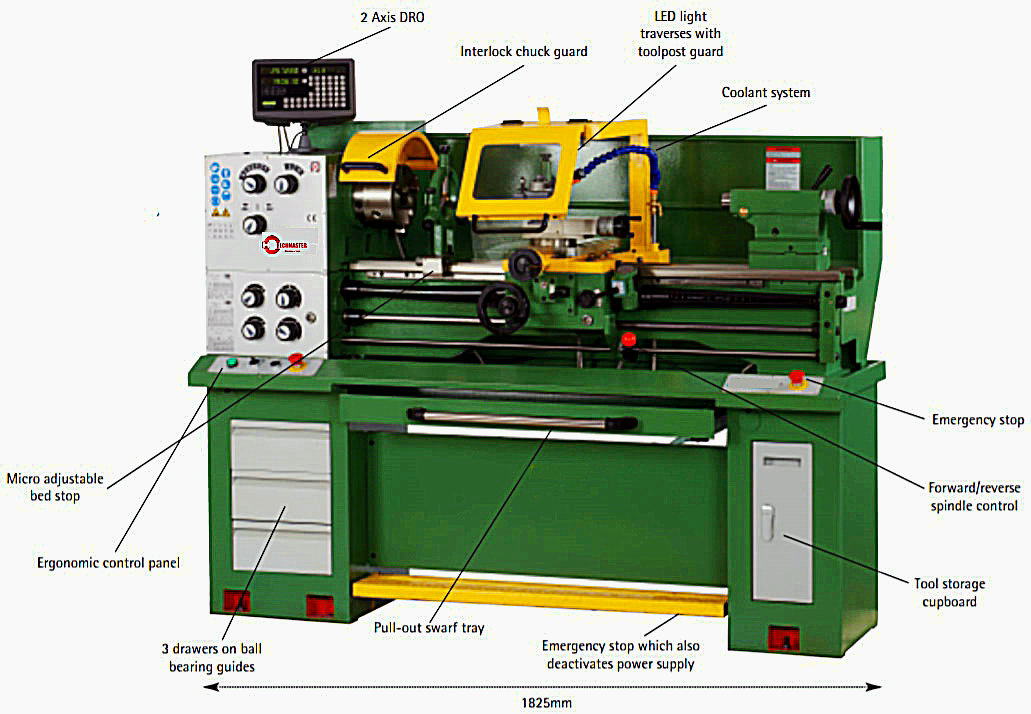

TURNER360X1000 PRO-

TURNER360X1000 PRO

a solidly constructed universal lathe, offering a wide range of applications. Features of this model include the large turning diameter of 360 mm and the 52 mm spindle bore. Its construction (design, performance, feeds etc) covers all needs for training purposes, as well as for tool shops and repair shops.

Properties

Solid prism-shaped machine bed features additional reinforcements to keep vibrations to a minimum

52 mm spindle bore to machine large shaft diameters comes standard

Ideal for processing of steel, non-ferrous materials and plastics

Removeable bridge allows machining of workpieces with a big diameter

Chip tray extracts to front, keeping space requirements to a minimum

Clear arranged speed and feed control settings, smooth operation and accurate control

Electro-magnetic foot brake reduces downtime

State-of-the-art spindle bedding with high-quality, angular ball bearings

Grey cast-iron machine bed, inductive hardened and polished

High spindle concentricity (≤ 0,009 mm)

Hardened and polished spindle runs in oil bath

Tailstock, spindle stock and all guides are adjustable

Tailstock can be adjusted ± 5 mm for taper turning

Distance between centers

1000 mm

Center height

180 mm

Swing over bed

360 mm

Swing over gap*

502 mm

Swing over cross slide

220 mm

Bed width

185 mm

Spindle bore

52 mm

Spindle nose fixture

DIN 55029, D1-5

Speed range

(8) 70 - 2000 rpm

Longitudinal feed

(32) 0,052 - 1,392 mm/rev.

Cross feed

(32) 0,014 - 0,380 mm/rev.

Metric thread

(26) 0,4 - 7,0 mm

Inch thread

(34) 4 - 56 threads/1“

Diameter of tailstock sleeve

42 mm

Travel of tailstock sleeve

100 mm

Taper of tailstock sleeve

MT 4

Motor power output S1 100%

1,5 kW (400 V)

Motor power input S6 40%

2,2 kW (400 V)

Machine dimension (W x D x H)

1825 x 750 x 1600 mm

Weight approx.

575 kg

* Removeable bed length: 205 mm

a solidly constructed universal lathe, offering a wide range of applications. Features of this model include the large turning diameter of 360 mm and the 52 mm spindle bore. Its construction (design, performance, feeds etc) covers all needs for training purposes, as well as for tool shops and repair shops.

Properties

Solid prism-shaped machine bed features additional reinforcements to keep vibrations to a minimum

52 mm spindle bore to machine large shaft diameters comes standard

Ideal for processing of steel, non-ferrous materials and plastics

Removeable bridge allows machining of workpieces with a big diameter

Chip tray extracts to front, keeping space requirements to a minimum

Clear arranged speed and feed control settings, smooth operation and accurate control

Electro-magnetic foot brake reduces downtime

State-of-the-art spindle bedding with high-quality, angular ball bearings

Grey cast-iron machine bed, inductive hardened and polished

High spindle concentricity (≤ 0,009 mm)

Hardened and polished spindle runs in oil bath

Tailstock, spindle stock and all guides are adjustable

Tailstock can be adjusted ± 5 mm for taper turning

Distance between centers

1000 mm

Center height

180 mm

Swing over bed

360 mm

Swing over gap*

502 mm

Swing over cross slide

220 mm

Bed width

185 mm

Spindle bore

52 mm

Spindle nose fixture

DIN 55029, D1-5

Speed range

(8) 70 - 2000 rpm

Longitudinal feed

(32) 0,052 - 1,392 mm/rev.

Cross feed

(32) 0,014 - 0,380 mm/rev.

Metric thread

(26) 0,4 - 7,0 mm

Inch thread

(34) 4 - 56 threads/1“

Diameter of tailstock sleeve

42 mm

Travel of tailstock sleeve

100 mm

Taper of tailstock sleeve

MT 4

Motor power output S1 100%

1,5 kW (400 V)

Motor power input S6 40%

2,2 kW (400 V)

Machine dimension (W x D x H)

1825 x 750 x 1600 mm

Weight approx.

575 kg

* Removeable bed length: 205 mm