- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

News

VMC640LH VERTICAL MACHINING CENTERYou are here: Home » Products » CNC MACHINE » VERTICAL MACHINING CENTER( LINEAR GUIDE WAYS) » VMC640LH VERTICAL MACHINING CENTER-

VMC640LH

MACHINE DETAILS

PARAMETERS(FANUC 0I MF SYSTEM, OTHER CNC CONTROLS OPTIONAL)

CODE

ITEM

DETAILS

1

WORKTABLE(WIDTH×LENGTH)

mm

900×400

2

T SLOTS

mm

3-18

3

DISTANCE BETWEEN T SLOTS

mm

100

4

MAX.LOAD BEARING OF WORKTABLE

kg

350

TRAVEL

5

X AXIS

mm

640

6

Y AXIS

mm

400

7

Z AXIS

mm

500

8

DISTANCE FROM COLUM TO SPINDLE CENTER

mm

476

9

DISTANCE FROM TABLE TOP SURFACE TO SPINDLE NOSE

mm

120-620

SPINDLE

10

SPINDLE HOLE TAPER

BT40

11

SPINDLE SPEED RANGE

r/min

20-8000

12

THE TRANSMISSIONOF SPINDLE BOX

BELT TYPE

13

MAIN MOTOR MODEL

βiI6/ 12000

14

SERVO MAIN MOTOR RATED POWER

kw

5.5

15

SERVO MAIN MOTOR 30MINS POWER

kw

7.5

16

SERVO MAIN MOTOR RATED OUTPUT TORQUE

Nm

26.3

17

SPINDLE PART DYNAMIC BALANCE TYPE

G1

18

SPINDLE ACCURACY

SPINDLE FACE RUNOUT:0.005mm

SPINDLE RADIAL RUNOUT :NEAR-END 0.007mm

TOOLS HOLDER SIZE

19

TOOLS HOLDER STANDARD

MSA403 BT40

20

RIVET STANDARD

MSA403 P40T-1

FEED

21

X/Y FEED MOTOR MODEL

βiSC 8/3000

22

X/Y FEED MOTOR MAX.SPEED

r/min

3000

23

X/Y FEED MOTOR RATED POWER

kw

1.2

24

X/Y FEED MOTOR RATED OUTPUT TORQUE

Nm

7

25

Z AXIS FEED MOTOR MODEL

βiSC 22B/2000

26

Z AXIS FEED MOTOR MAX SPEED

r/min

2000

27

Z FEED MOTOR RATED POWER

kw

2.5

28

Z FEED MOTOR RATED OUTPUT TORQUE

Nm

20

29

X/Y FEED RATE

m/min

30

30

Z FEED RATE

m/min

24

31

CUTTING FEED SPEED

mm/min

15000

TOOL MAGAZINE

32

TOOLS MAGAZINE MODEL

MANIPULATOR

33

CAPACITY

pcs

16

34

FULL TOOLS MAX TOOL DIAMETER

mm

Ф78

35

NEIGHBOR EMPTY TOOL DIAMETER

mm

Ф120

36

MAX.TOOLS ALLOWABLE WEIGHT

kg

8

37

MAX.TOOLS ALLOWABLE LENGTH

mm

220

38

TOOL CHANGE TIME

s

3.5

39

TOOL CHANGE WAY

FORWARD/REVERSAL

POWER SOURCE

40

MACHINE ELECTRIC CAPACITY

KVA

20

41

COOLING PUMP FLOW RATE

L/min

40

42

MACHINE COMPRESSED AIR

kg

6~8

43

POWER REQUIREMENT

380V±10% 50Hz

ENVIRONMENTAL REQUIREMENT

44

ENVIRONMENTAL TEMPERATURE REQUIREMENT

0℃~40℃

45

RELATIVE HUMIDITY

20%~80%

MACHINE SIZE

46

MACHINE DIMENSION

mm

2200×2100×2600

47

MACHINE WEIGHT

kg

3700

48

MACHINE SHIELD

FULL PROTECT

ACCURACY

49

X/Y/Z POSITION ACCURACY

mm

±0.010

50

X/Y/Z RE-POSITION ACCURACY

mm

±0.005

OTHERS

X/Y/Z LINEAR MOTION SLIDE WAY

OIL-WATER SEPARATION

PRE-TENSION FOR BALL SCREW

SPINDLE AIR SEALING

RIGID TAPPING

AUTO LUBRICATION SYSTEM

WORKPIECE COOLING SYSTEM

RS232 INTERFACE

M30 AUTOMATIC POWER-OFF SYSTEM

PORTABLE BLOWING DUST AIR GUN

ELECTRICAL CABINET HEAT EXCHANGER

MANUAL PULSE GENERATOR

ALL OVER PROTECTION SHIELD

ANCHOR BOLTS AND PADS

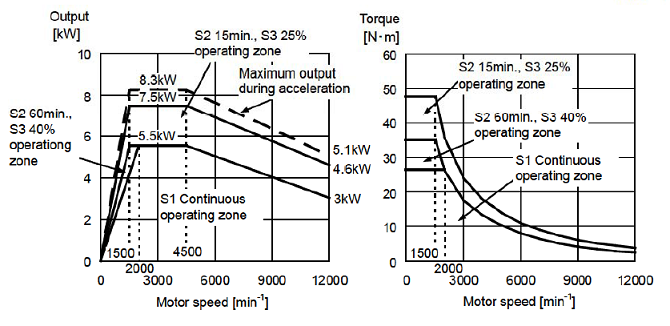

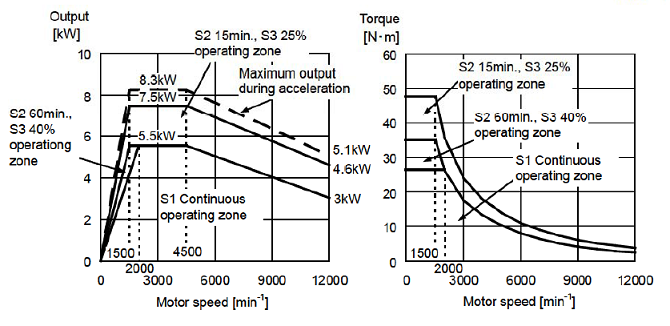

SPINDLE TORQUE AND MOTOR OUTPUT

MACHINE DETAILS

PARAMETERS(FANUC 0I MF SYSTEM, OTHER CNC CONTROLS OPTIONAL)

CODE

ITEM

DETAILS

1

WORKTABLE(WIDTH×LENGTH)

mm

900×400

2

T SLOTS

mm

3-18

3

DISTANCE BETWEEN T SLOTS

mm

100

4

MAX.LOAD BEARING OF WORKTABLE

kg

350

TRAVEL

5

X AXIS

mm

640

6

Y AXIS

mm

400

7

Z AXIS

mm

500

8

DISTANCE FROM COLUM TO SPINDLE CENTER

mm

476

9

DISTANCE FROM TABLE TOP SURFACE TO SPINDLE NOSE

mm

120-620

SPINDLE

10

SPINDLE HOLE TAPER

BT40

11

SPINDLE SPEED RANGE

r/min

20-8000

12

THE TRANSMISSIONOF SPINDLE BOX

BELT TYPE

13

MAIN MOTOR MODEL

βiI6/ 12000

14

SERVO MAIN MOTOR RATED POWER

kw

5.5

15

SERVO MAIN MOTOR 30MINS POWER

kw

7.5

16

SERVO MAIN MOTOR RATED OUTPUT TORQUE

Nm

26.3

17

SPINDLE PART DYNAMIC BALANCE TYPE

G1

18

SPINDLE ACCURACY

SPINDLE FACE RUNOUT:0.005mm

SPINDLE RADIAL RUNOUT :NEAR-END 0.007mm

TOOLS HOLDER SIZE

19

TOOLS HOLDER STANDARD

MSA403 BT40

20

RIVET STANDARD

MSA403 P40T-1

FEED

21

X/Y FEED MOTOR MODEL

βiSC 8/3000

22

X/Y FEED MOTOR MAX.SPEED

r/min

3000

23

X/Y FEED MOTOR RATED POWER

kw

1.2

24

X/Y FEED MOTOR RATED OUTPUT TORQUE

Nm

7

25

Z AXIS FEED MOTOR MODEL

βiSC 22B/2000

26

Z AXIS FEED MOTOR MAX SPEED

r/min

2000

27

Z FEED MOTOR RATED POWER

kw

2.5

28

Z FEED MOTOR RATED OUTPUT TORQUE

Nm

20

29

X/Y FEED RATE

m/min

30

30

Z FEED RATE

m/min

24

31

CUTTING FEED SPEED

mm/min

15000

TOOL MAGAZINE

32

TOOLS MAGAZINE MODEL

MANIPULATOR

33

CAPACITY

pcs

16

34

FULL TOOLS MAX TOOL DIAMETER

mm

Ф78

35

NEIGHBOR EMPTY TOOL DIAMETER

mm

Ф120

36

MAX.TOOLS ALLOWABLE WEIGHT

kg

8

37

MAX.TOOLS ALLOWABLE LENGTH

mm

220

38

TOOL CHANGE TIME

s

3.5

39

TOOL CHANGE WAY

FORWARD/REVERSAL

POWER SOURCE

40

MACHINE ELECTRIC CAPACITY

KVA

20

41

COOLING PUMP FLOW RATE

L/min

40

42

MACHINE COMPRESSED AIR

kg

6~8

43

POWER REQUIREMENT

380V±10% 50Hz

ENVIRONMENTAL REQUIREMENT

44

ENVIRONMENTAL TEMPERATURE REQUIREMENT

0℃~40℃

45

RELATIVE HUMIDITY

20%~80%

MACHINE SIZE

46

MACHINE DIMENSION

mm

2200×2100×2600

47

MACHINE WEIGHT

kg

3700

48

MACHINE SHIELD

FULL PROTECT

ACCURACY

49

X/Y/Z POSITION ACCURACY

mm

±0.010

50

X/Y/Z RE-POSITION ACCURACY

mm

±0.005

OTHERS

X/Y/Z LINEAR MOTION SLIDE WAY

OIL-WATER SEPARATION

PRE-TENSION FOR BALL SCREW

SPINDLE AIR SEALING

RIGID TAPPING

AUTO LUBRICATION SYSTEM

WORKPIECE COOLING SYSTEM

RS232 INTERFACE

M30 AUTOMATIC POWER-OFF SYSTEM

PORTABLE BLOWING DUST AIR GUN

ELECTRICAL CABINET HEAT EXCHANGER

MANUAL PULSE GENERATOR

ALL OVER PROTECTION SHIELD

ANCHOR BOLTS AND PADS

SPINDLE TORQUE AND MOTOR OUTPUT