English

- Home

- 552-2819255info@qqqqq.com1111-1111 1111GOOD MACHINE TOOLS FOR GOOD PEOPLE . CONTACT US TO HAVE GOOD FRIENDS AND GOOD MACHINE TOOLS .

Products

- TURNING

- MILLING

- DRILLING MACHINE

- DRILL PRESS

- MAGNETIC DRILL

- SAWS

- POWER TOOLS

- MACHINE TOOLS ACCESSORIES

- WOODWORKING MACHINE

- BENCH GRINDER / BELT DISC SANDER

- METAL FORMING MACHINE

- ARBOR PRESS MACHINE

- 3-IN-1 MACHINE

- BENDING MACHINE

- HYDRAULIC PRESS MACHINE

- ROLLER MACHINE

- SHEARING MACHINE

- NOTCHING MACHINE

- IRON WORKER

- CORNER ASSEMBLE MACHINE

- CORNER AUTOMATIC PRODUCTION LINE

- HAND SHEAR / MANUAL SHEAR

- HYD SEAM LOCK MACHINE

- MACHINE FOR METAL SHEET AND PIPE

- MANUAL C CLEAT MACHINE

- ROLL FORMIING MACHINE SERIES

- ROUND PIPES SEAM CLOSING MACHINE

- SWAGING MACHINE SERIES

- Cizalla, Plegadora, Curvadora

- CNC MACHINE

- SURFACE GRINDER

- AUTO MAINTAINANCE EQUIPMENT

- SHAPING MACHINE

- SLOTTING MACHINE

- HELICAL CUTTERHEADS

- PIPE MACHINERY /PIPE TOOL

- SPIRIAL CUTTERHEADS

- SANDING MACHINES

- GARAGE EQUIPMENT

- WELDING MACHINE

- SPINNING RIVETTER

- SQUARENESS DUCT MACHINERY SERIES

- BENCH DRILLING / TAPPING MACHINE

- PORTABLE LINE BORING MACHINE

- REAL EXPORT MACHINE TOOL;S FOR CUSTOMERS

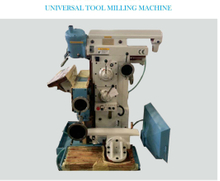

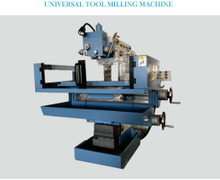

TOOL MILLING MACHINE